Here you will find current reports on the status of the project. Information on our public relations work and other news.

Call for support for financing by crowdfunding!

A milestone in the aviation and industrial history of the Rhine Valley is to be brought back to life. Please support the return of the Do X to Altenrhein here ……

….. www.lokalhelden.ch/dox-flugschiff

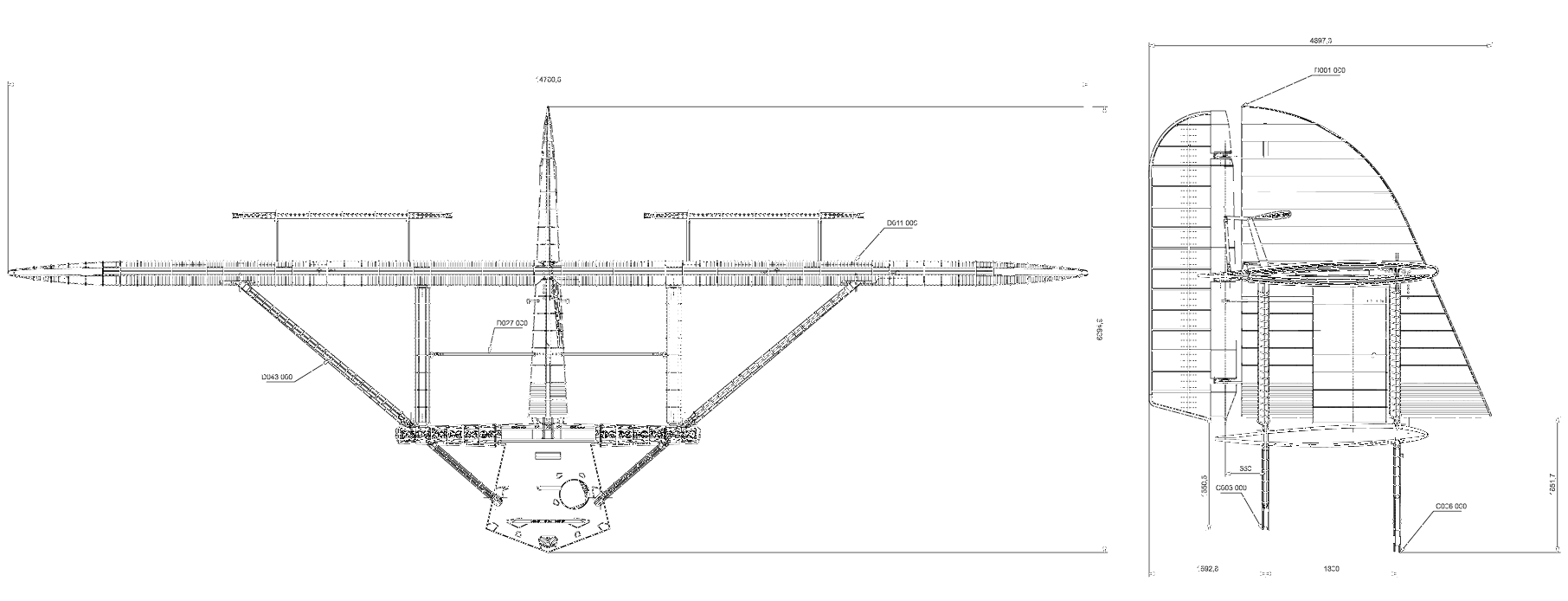

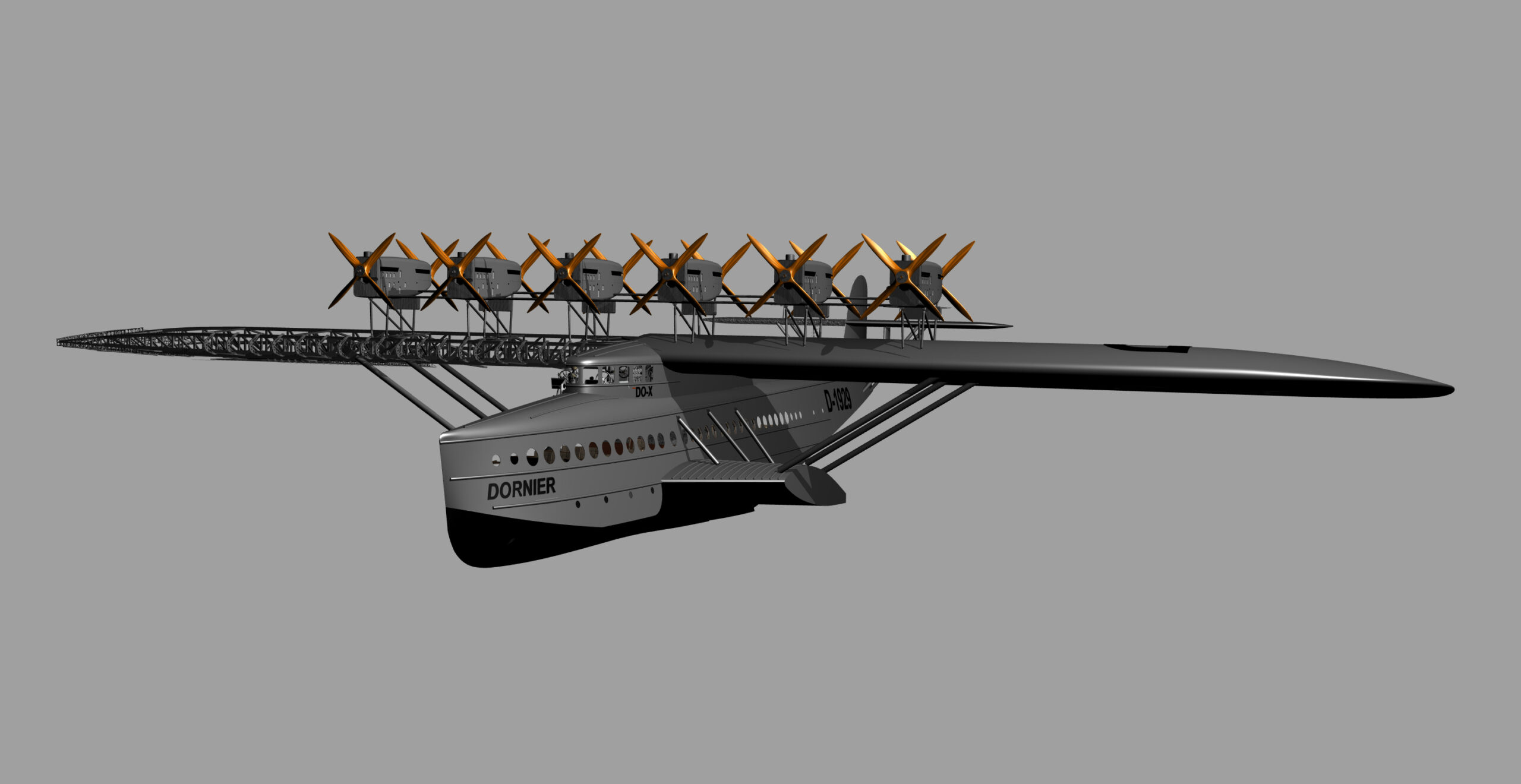

The Do X was a visionary project by Claude Dornier. It was the world’s first wide-body passenger aircraft. The size and capacity of the Do X surpassed the aircraft sizes of the time many times over. It was 40 metres long, had a wingspan of 48 metres, three decks and room for 65 passengers. This went beyond the usual dimensions of the time.

It was designed and constructed in Friedrichshafen and built in the factory and industrial halls in Altenrhein, which were specially erected in 1926. In the following years, Dornier proved that his vision could be realised. He demonstrated this with a spectacular flight with 169 people on board over Lake Constance and the highly publicised flight from Europe via West Africa and South America to New York and back.

Three aeroplanes were built in Altenrhein, but none of these impressive aircraft have been preserved. However, we have been working hard to restore the blueprints. You can find out more about the exciting history of the reconstruction below.

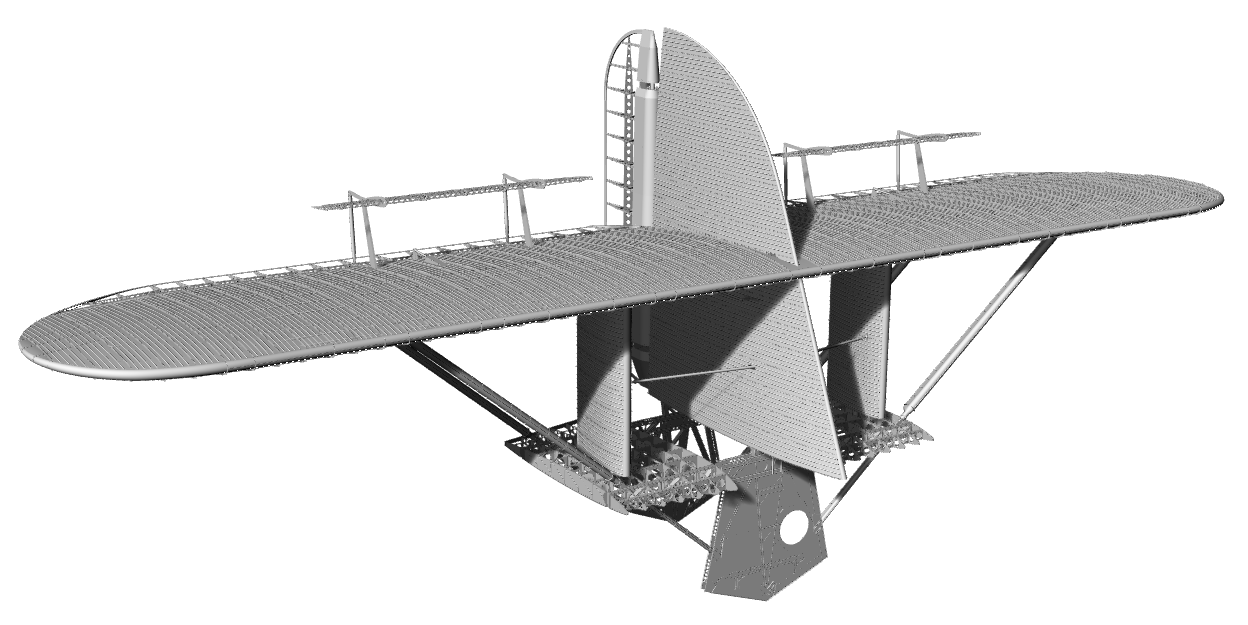

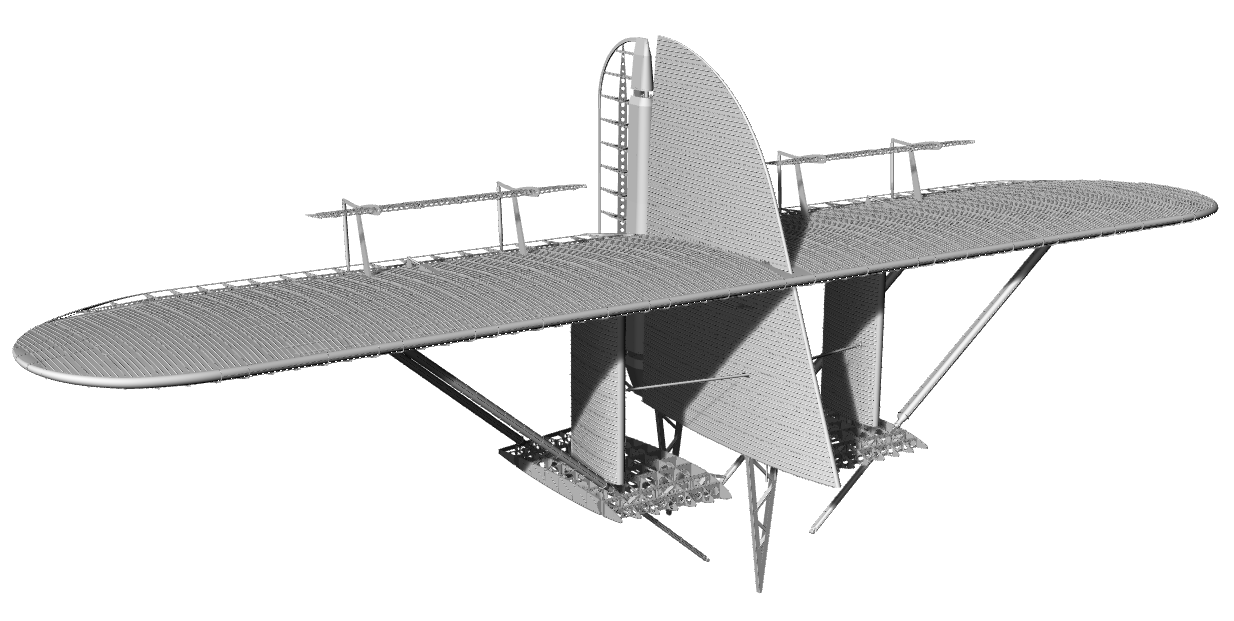

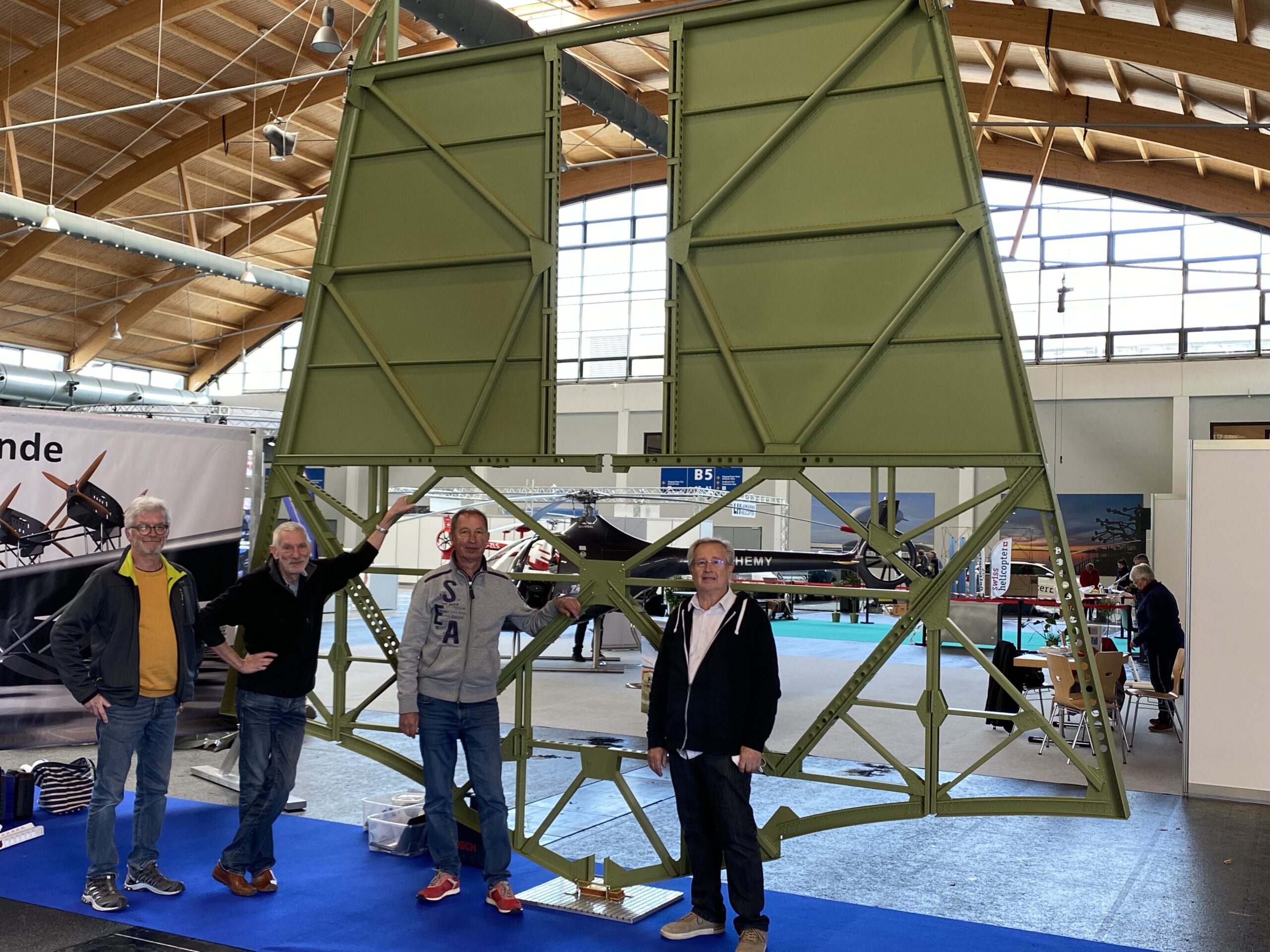

The aim of the replica is to create a static, true-to-original and fully accessible 1:1 model of the Do X. This replica of the Do X has already begun. The first construction phase, the foreship, from the tip of the aircraft to the base of the wing, is being built at the FFA Museum in Altenrhein/Switzerland. These first components show impressively that a realistic 1:1 replica of the Do X is possible – see for yourself.

And the replica will continue. Please support the return of the Do X to Altenrhein here ……

….. www.lokalhelden.ch/dox-flugschiff

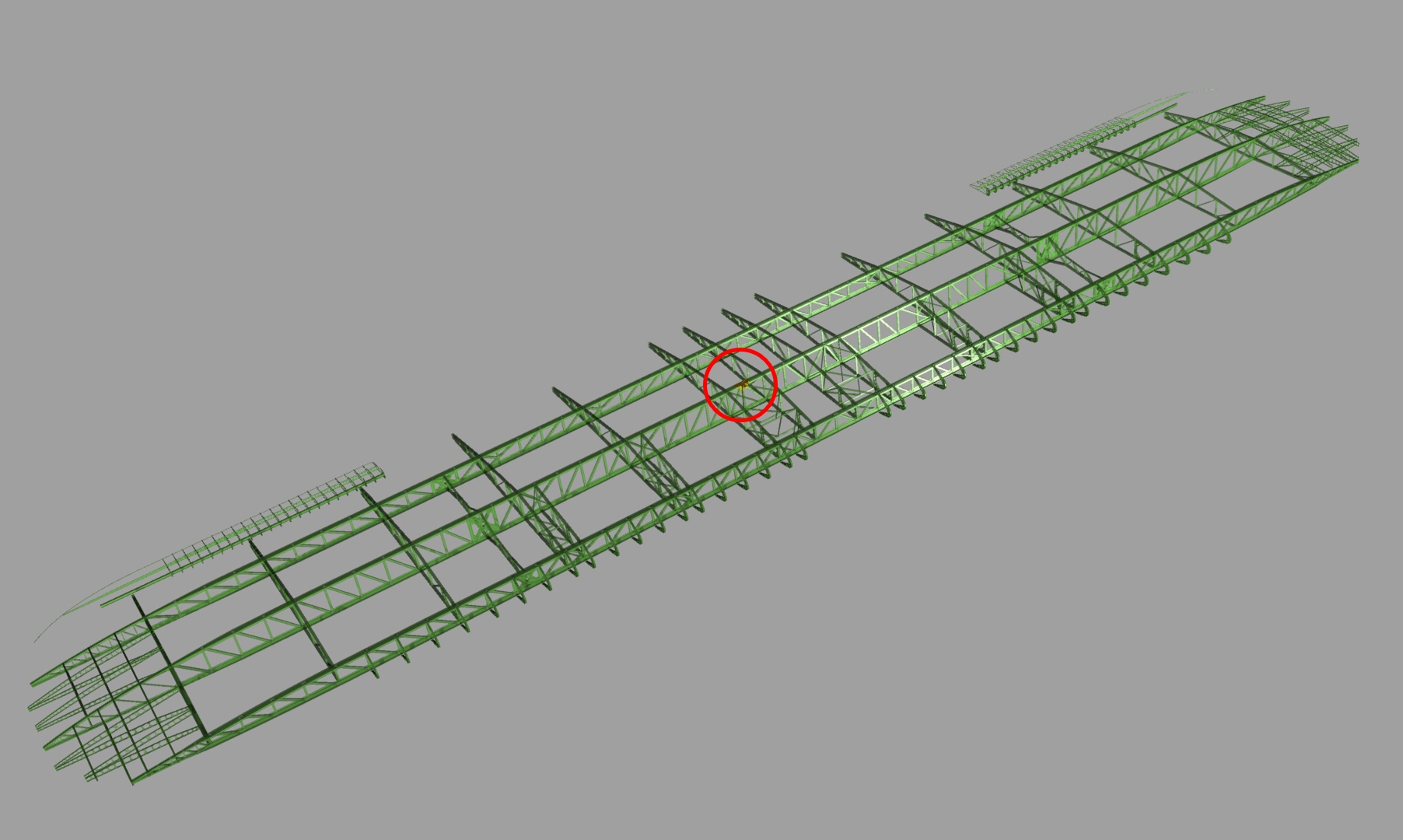

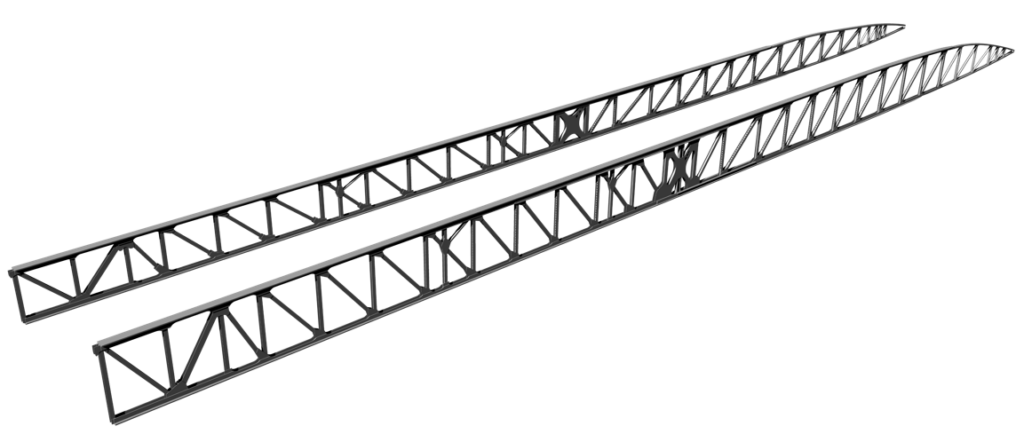

Result of the G10 structural work

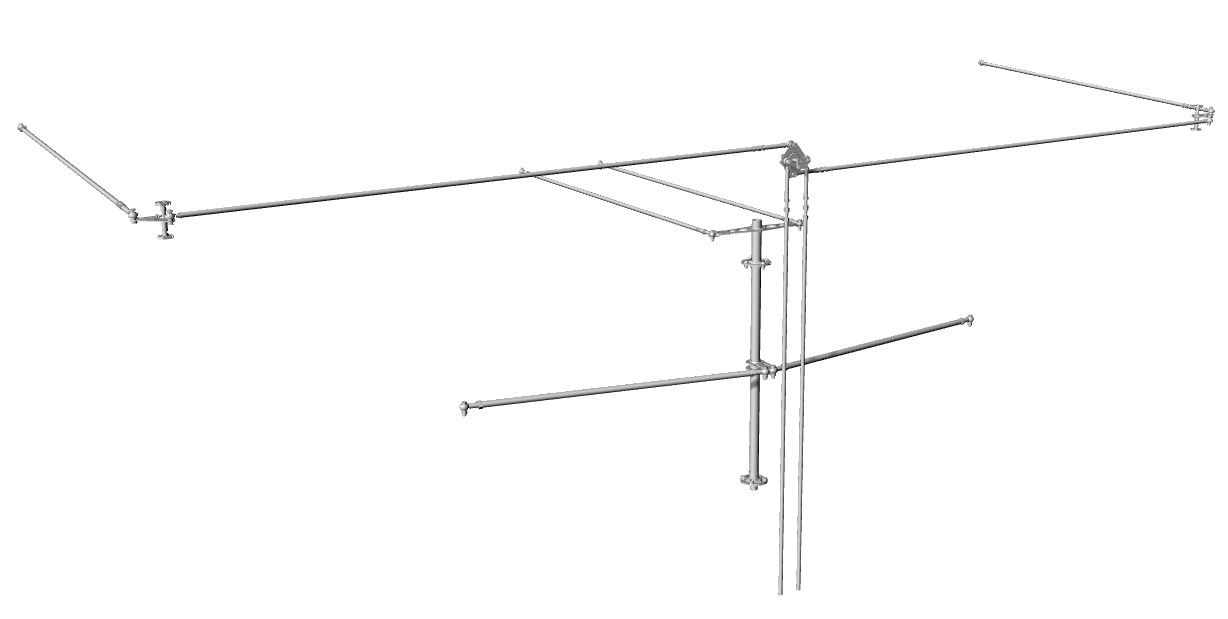

The 2nd JourFix for the reconstruction of the wing structure work was scheduled for the beginning of May. The task required the reconstruction of the front spar and the centre spar. The design and an overview drawing had to be submitted for JourFix 2. The results are the basis for further work on the wing structure.

The assembly of the Do X returns to Lake Constance!

Due to a lack of assembly space, the Do X was assembled for a time in Hildesheim in Lower Saxony. The location there was better than storing the components in a garage and made it possible to continue the assembly. This time is now over. From May 2024, the body will be on display at the Altenrhein Aviation and Vehicle Museum (FFA) in Altenrhein, Switzerland, where it will be continued. Incidentally, members of the Friends and Supporters of Do X e.V. have free admission to the FFA Museum.

This opportunity arose through discussions with the Vice President of the Swiss Aero Club Eastern Switzerland, Bruno Scherrer. In the enthusiasm that the Do X assembly will move to Altenrhein, a corresponding association was also founded on the Swiss side on 8 February, the Do X Verein Altenrhein, an association in accordance with Art. 60ff of the Swiss Civil Code (ZGB).

This association organised the necessary space for the installation site of the Do X superstructure.

The components were collected from Hildesheim on 10/11 April and transported directly to Altenrhein. The reassembly at the FAA Museum took place on 27 April.

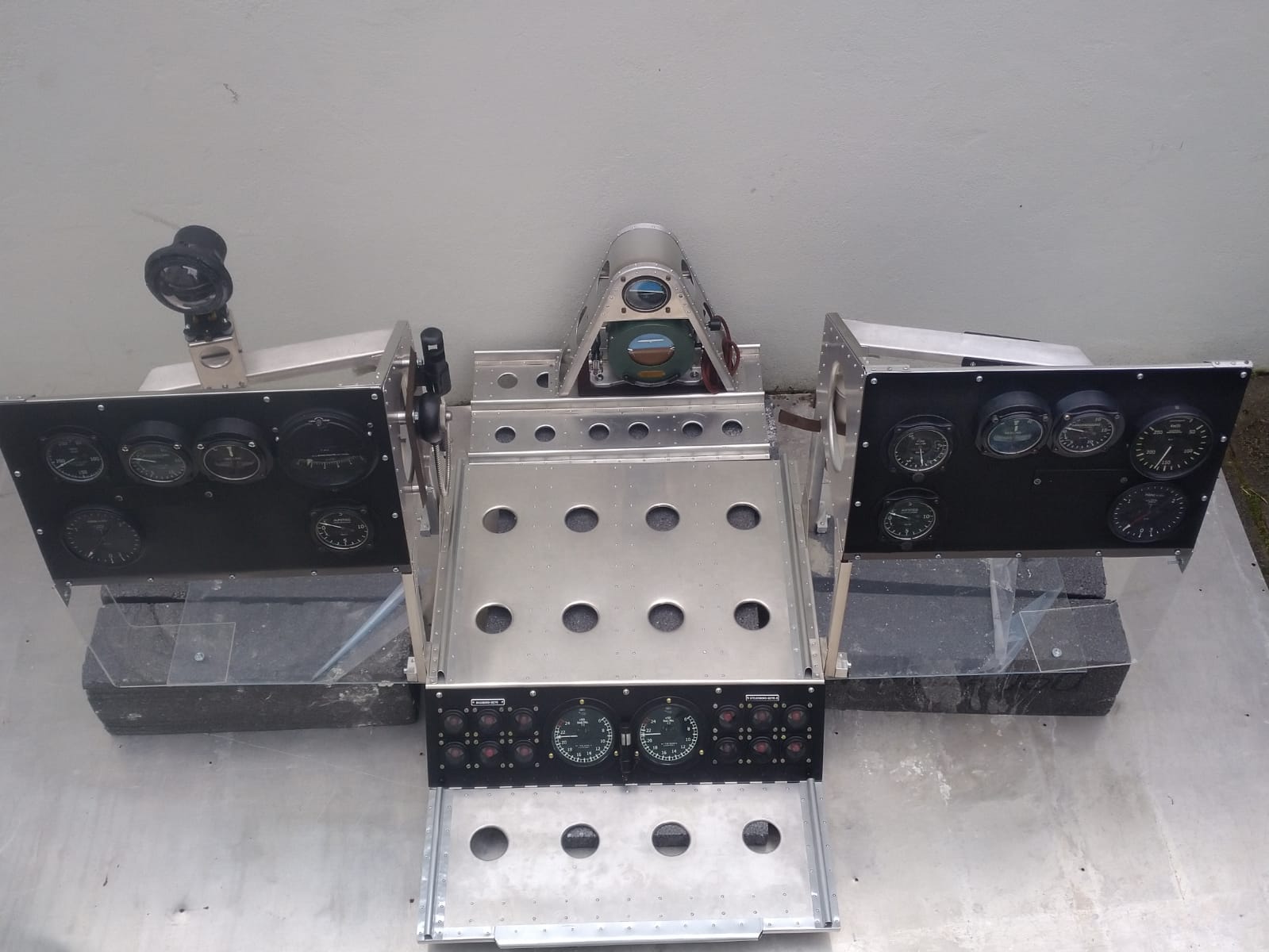

The Do X superstructure is located in the historic hall of the FAA Museum. An area 6.5 metres wide and 13 metres long is planned for the superstructure of the first expansion stage (construction stage A), the forecastle.

As all the components were dismantled into their main segments for transport, frame 44, consisting of three segments, first had to be reassembled and put to one side. The slipway, consisting of four segments, was then assembled and aligned with the available area for the Do X superstructure. In the third assembly stage, the two segments of the centre longeron were joined together and fixed to the slipway. Finally, the connecting elements of frame 44 were removed again, the frame was mounted on the centre longitudinal member and connected to the centre longitudinal member using the connecting elements.

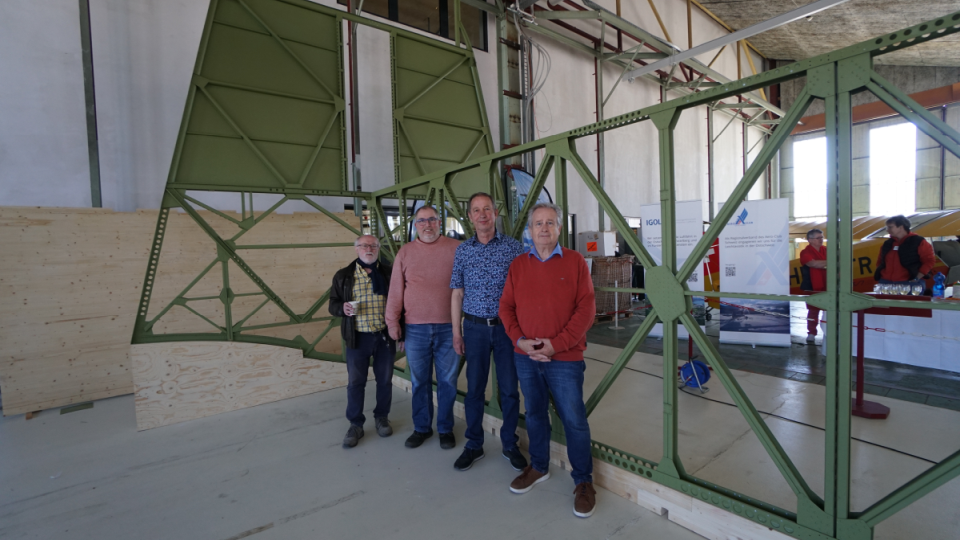

The set-up team from the Do X friends and supporters association (from left to right: Michael Witt, Thomas Unger, Richard Buck and Peter Kielhorn)

Participation in the Aero 2024

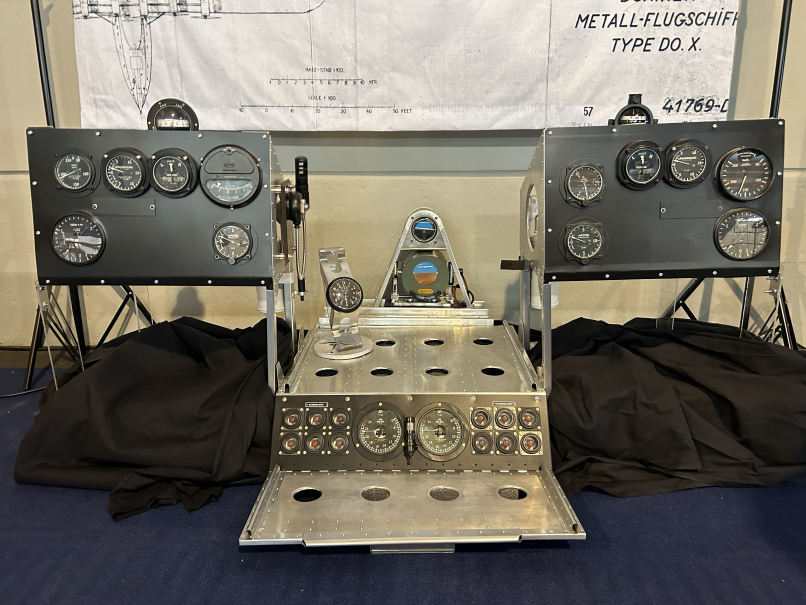

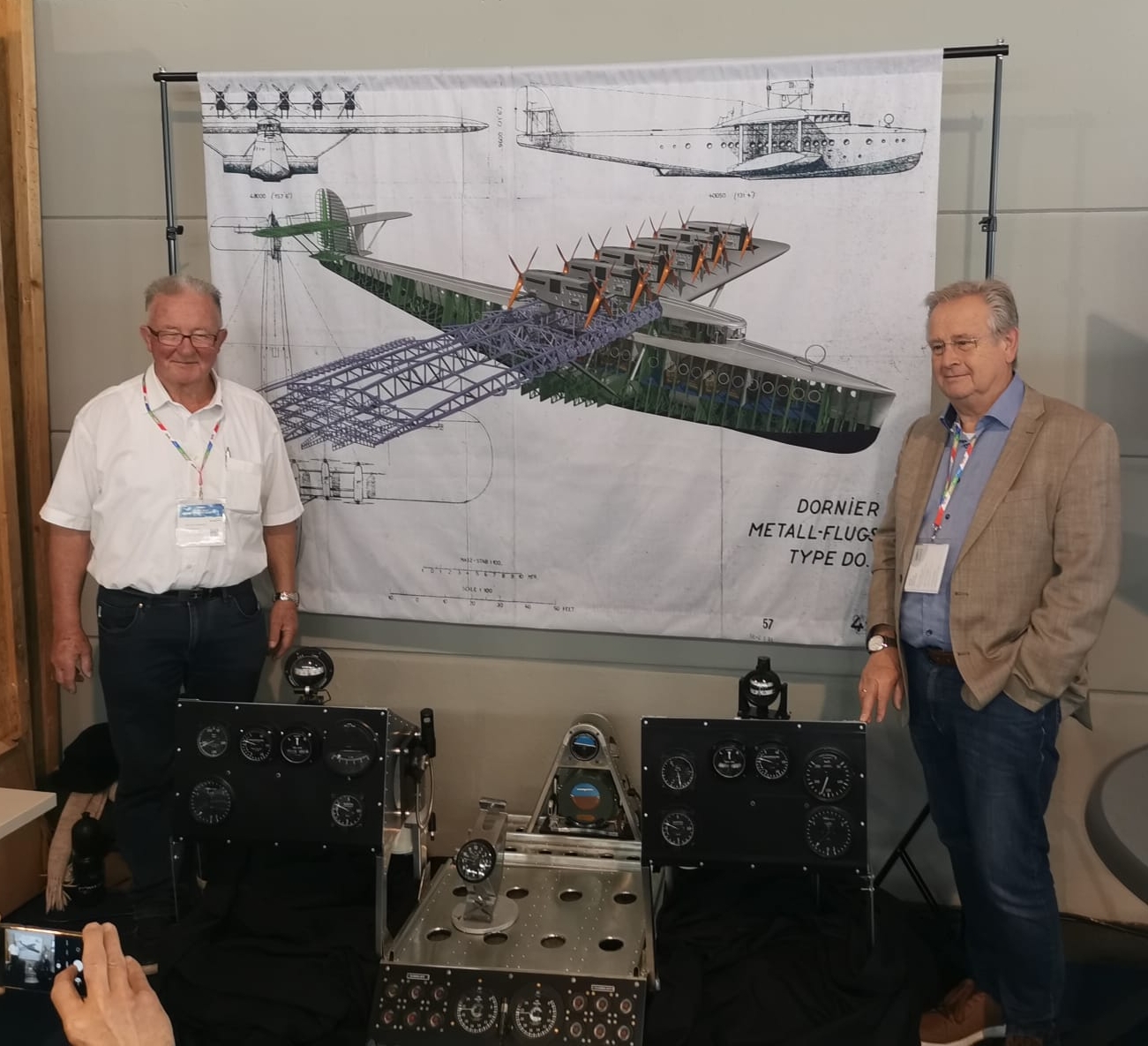

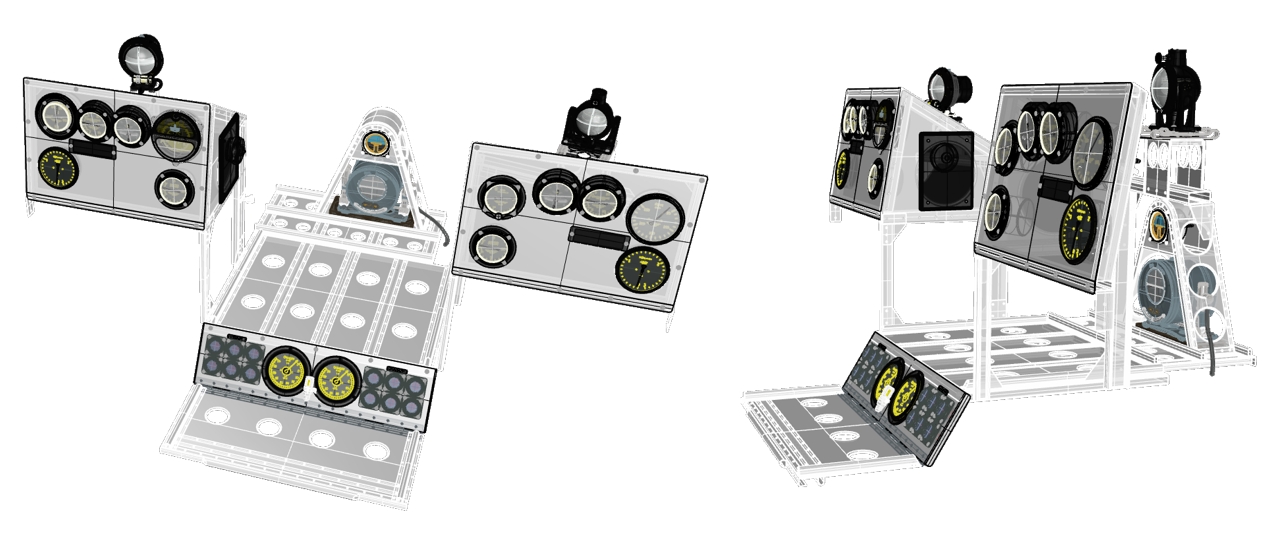

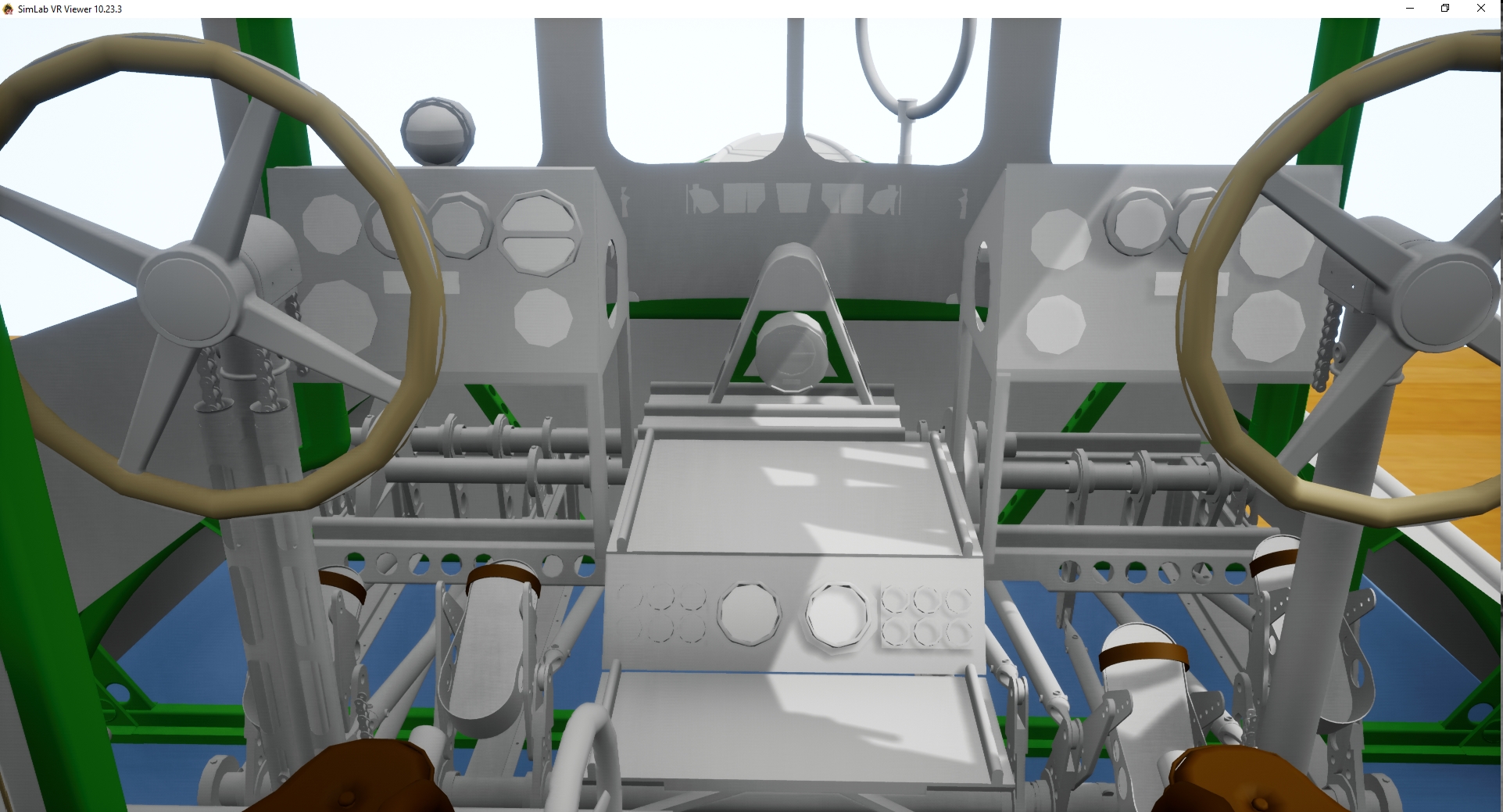

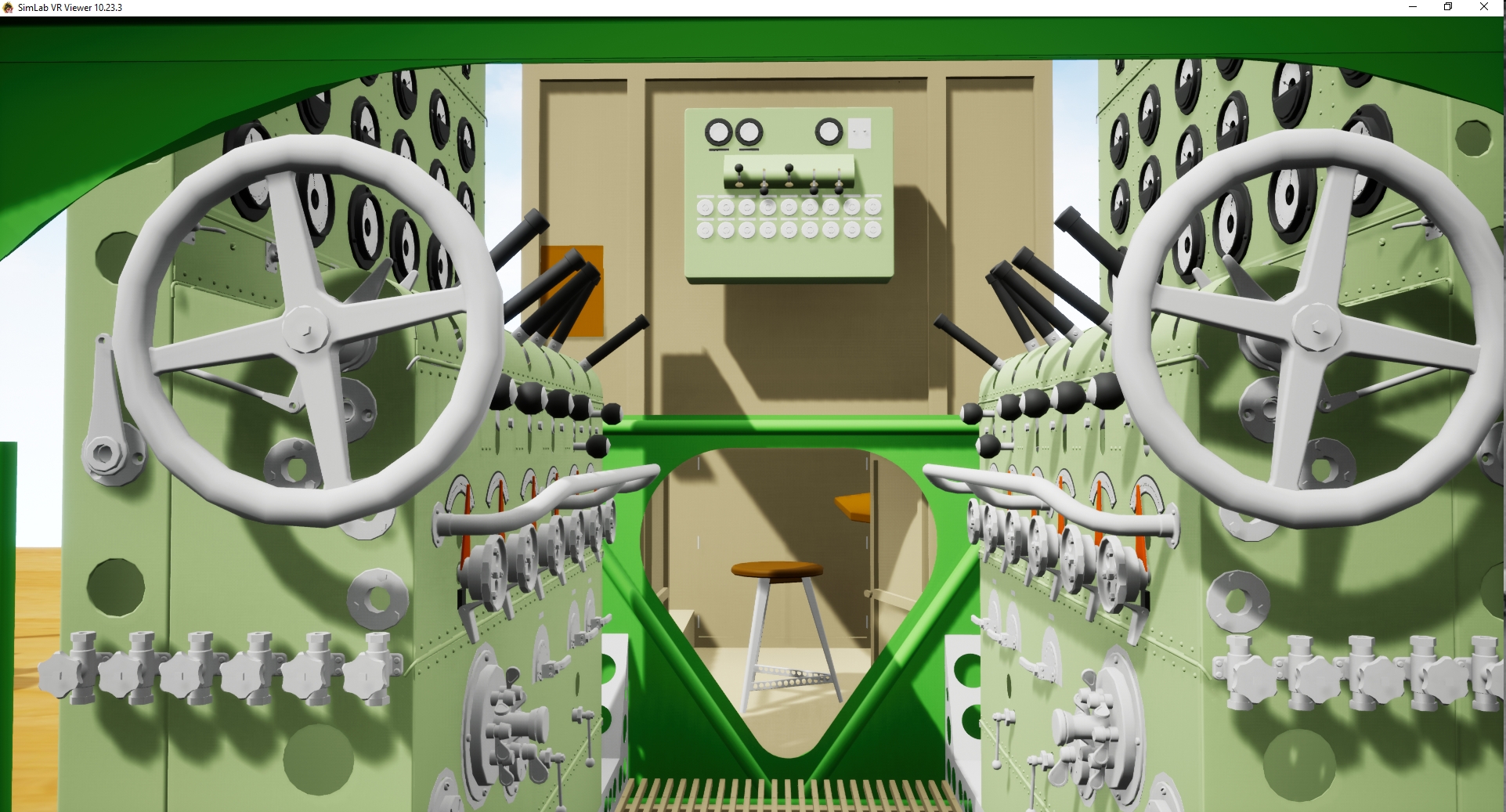

The Do X Circle of Friends and Sponsors once again took part in the Aero aviation trade fair in 2024. In addition to a video/virtual reality show, the Circle of Friends presented a replica of the Do X cockpit instruments, consisting of the pilot and co-pilot panel, the front centre panel for engine monitoring and the two artificial horizons in the rear centre of the cockpit.

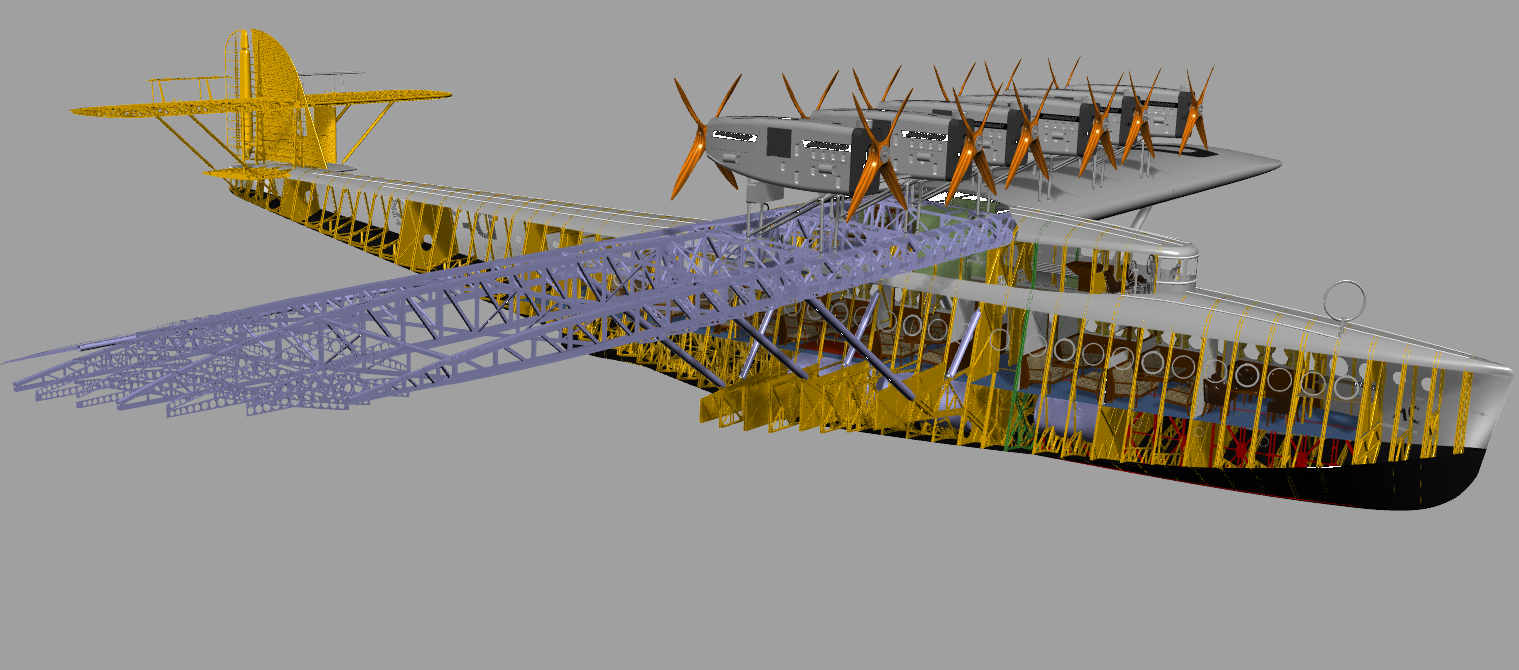

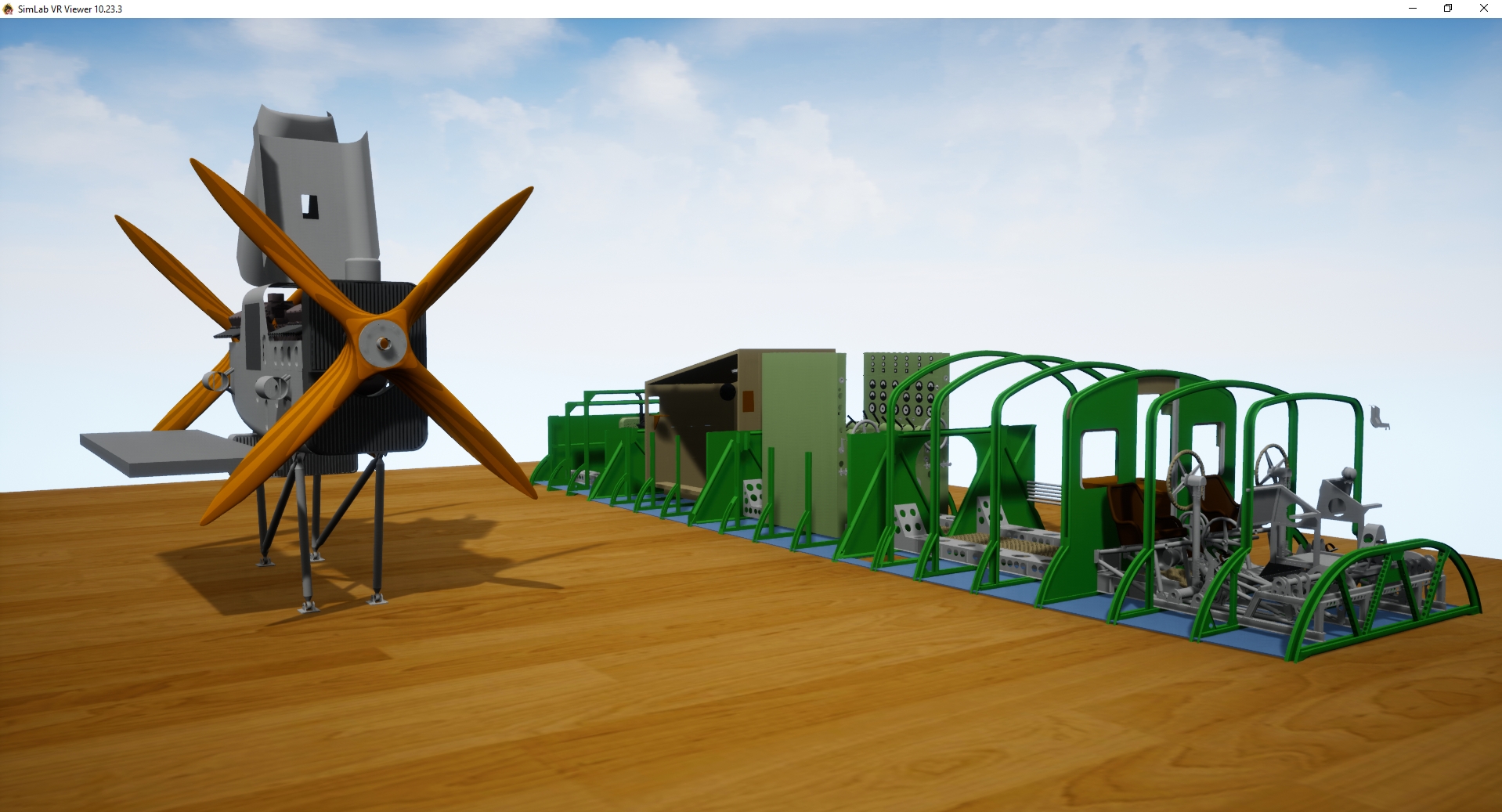

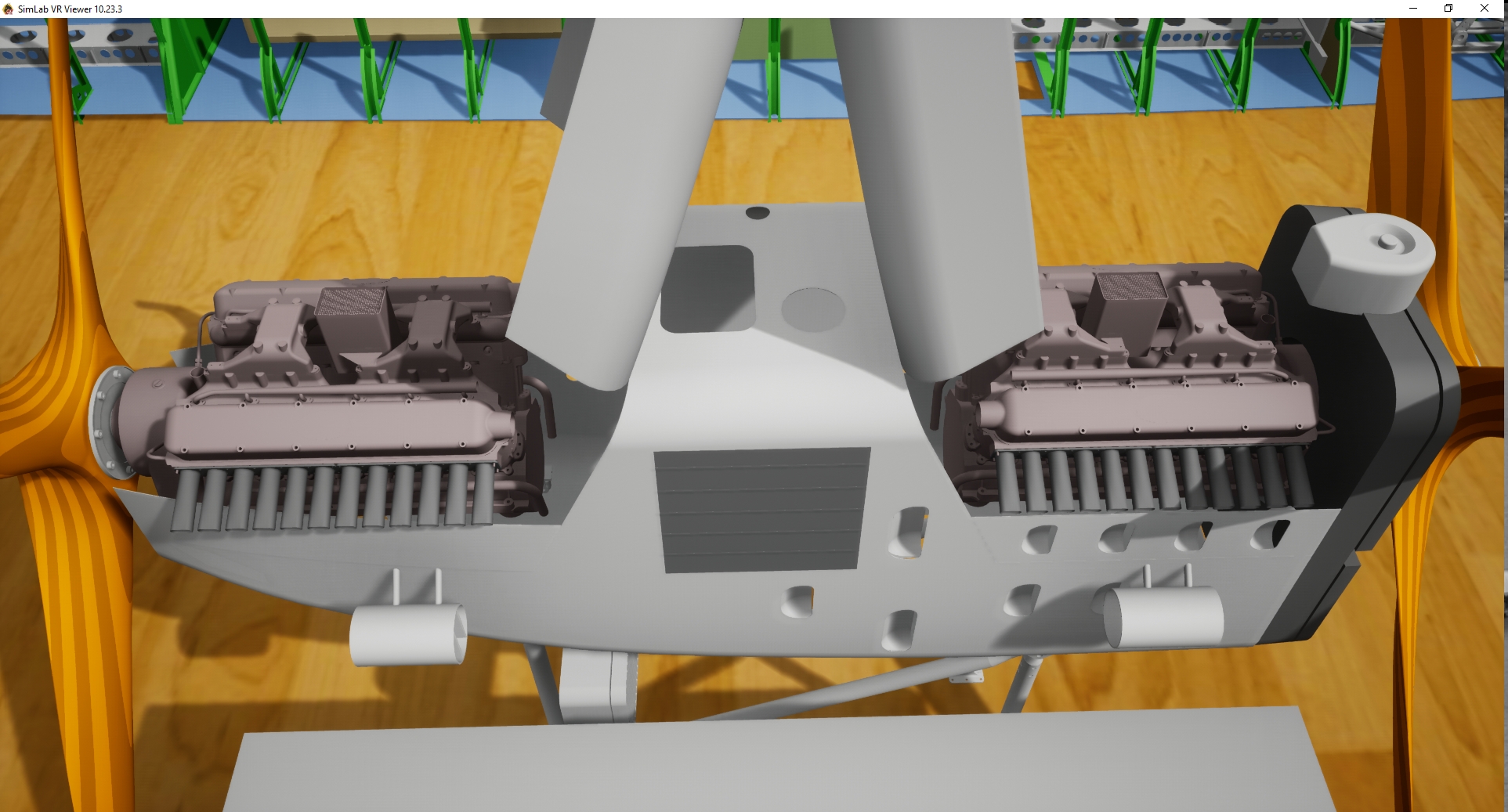

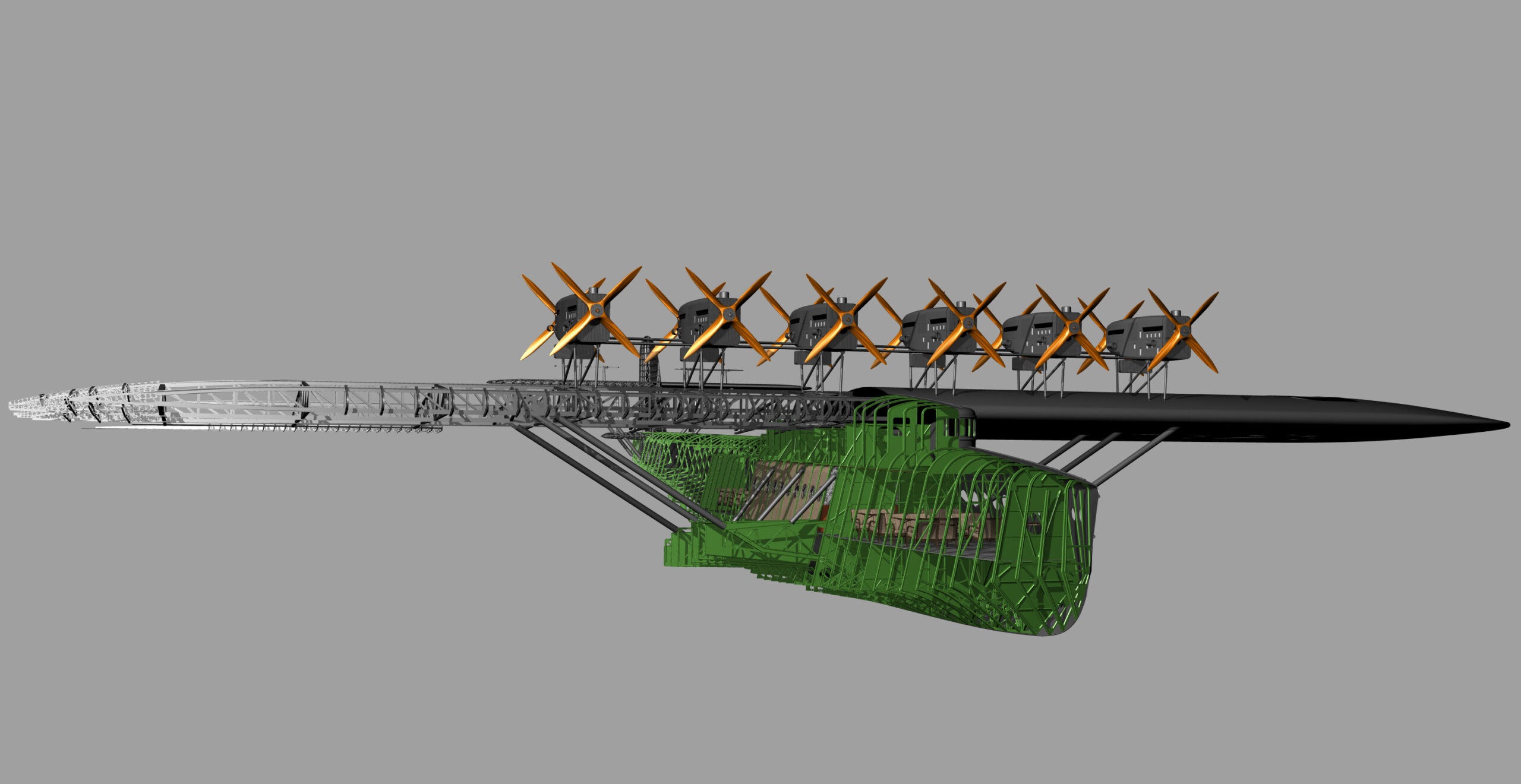

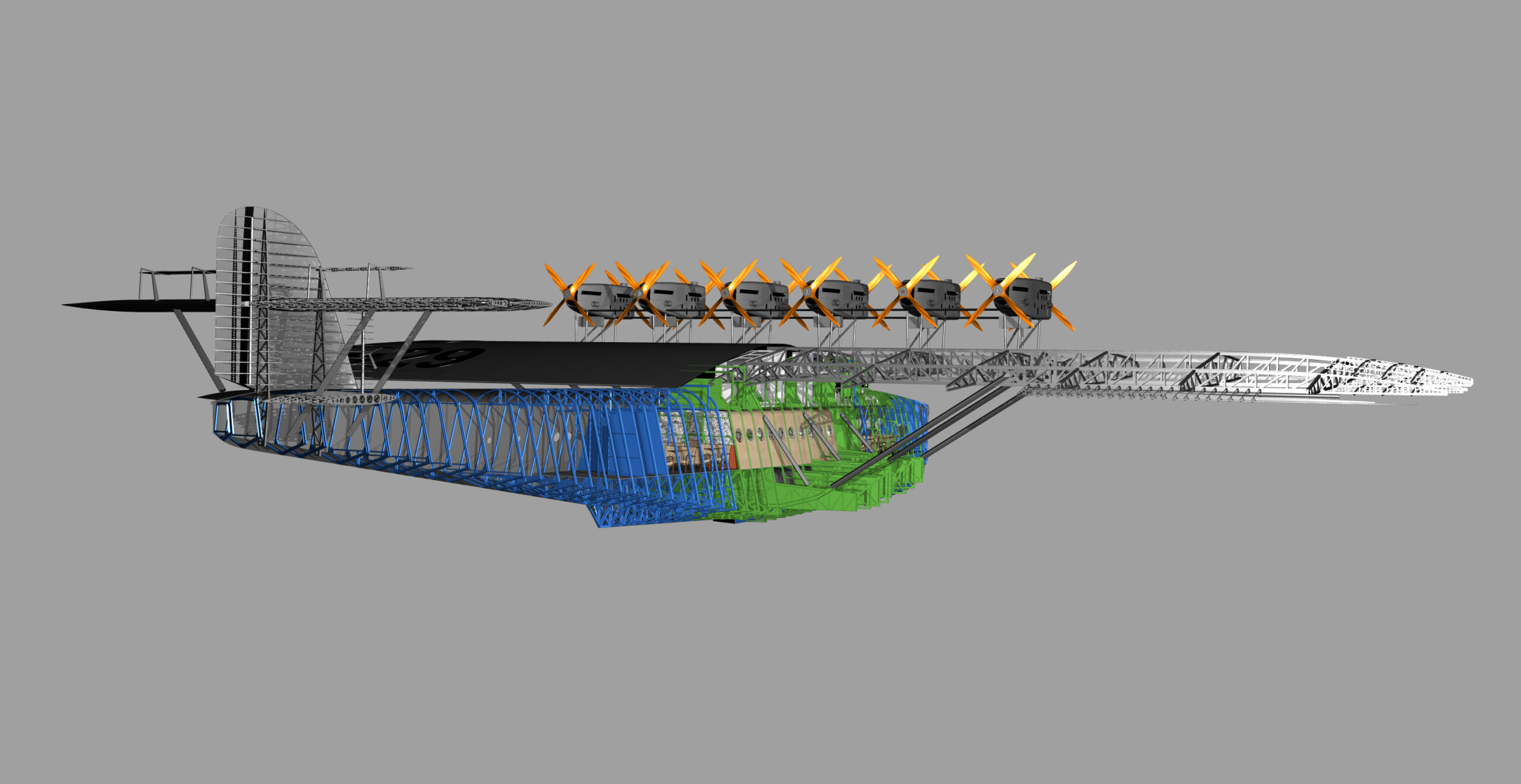

The virtual reality show features a virtual Do X museum with a Do X and many other details about the Do X, such as the Curtiss engine, an engine nacelle placed on the ground, an upper deck of the Do X placed on the ground and the current Do X superstructure. The main object, the Do X, is shown closed on the port side and open on the starboard side to show the intricate internal structure.

Herr Cohausz, Fachmann für historische Cockpitinstrumente, begutachtet die nachgebauten Do X Instrumente

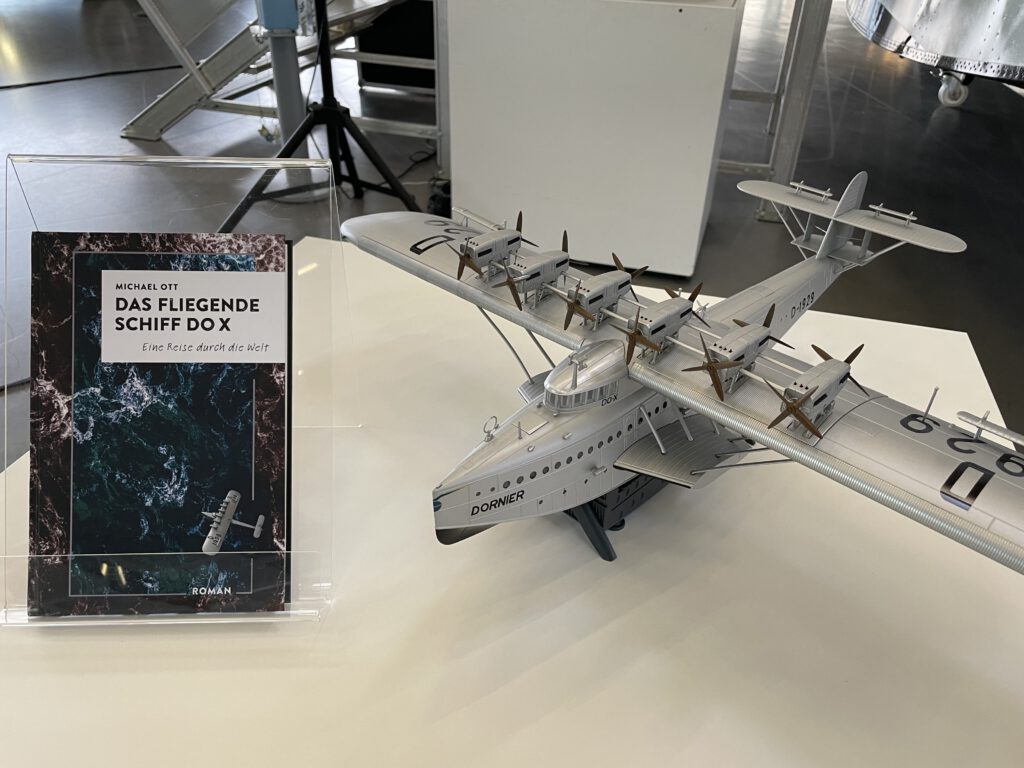

Book presentation: The Flying Ship Do X by Michael Ott (March 2024)

A special book presentation took place at the Dornier Museum on 21 March 2024. Michael Ott, a member of the Do X Circle of Friends, wrote this book but did not live to see it published. Michael Ott sadly passed away in autumn 2023.

Michael Ott’s circle of friends has set itself the task of publishing his book. Based on true events, the book tells the story of the American flight of the Do X, combined with the story of the relationship of the on-board mechanic Emil Martins*). The mechanic works at the Dornier aircraft factory in Friedrichshafen and is given the opportunity of a lifetime. He was to be part of the crew that was to fly the largest aeroplane in the world at the time from Lake Constance across the Atlantic to New York.

The well-researched details of the Do X’s ferry flight to the USA show what an adventure this flight was. And the circumstances of Emil Martins’ life change as a result of this journey, he experiences a much broader view of the world and when he makes an acquaintance on the South American trip, his life changes.

*) Emil Martins is a fictional character.

The various facets of the book were discussed in a somewhat different literary quartet.

The book is available in bookshops under ISBN 9789 4037 04791 or via the book’s website www.das-fliegende-schiff-do-x.com or via the Do X circle of friends and supporters (order by email to info@freundeskreis-do-x.de).

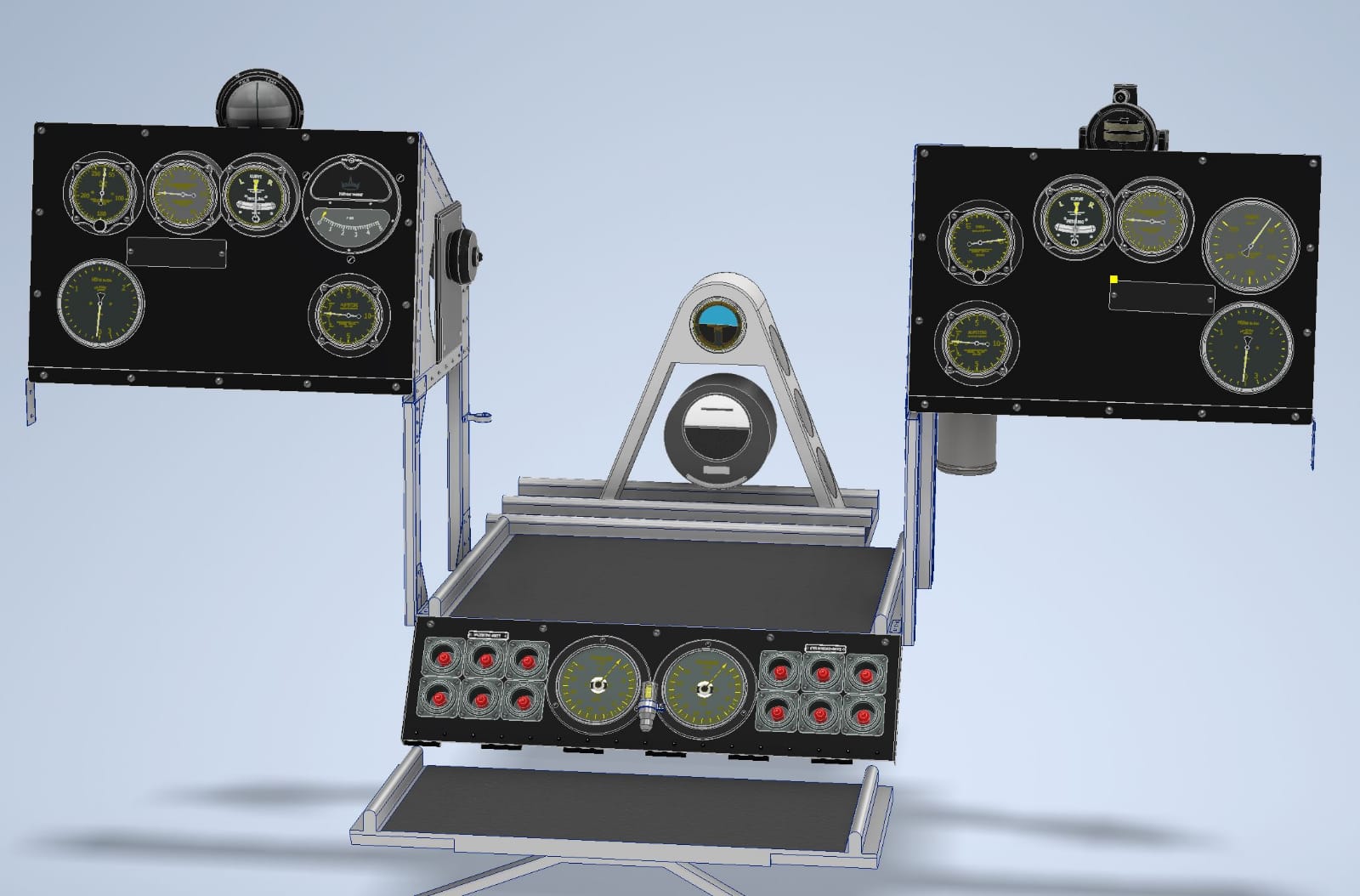

Reconstruction of the cockpit instrumentation ready (March 2024)

The rebuild of the cockpit instrumentation of the Do X is complete. The instrumentation consists of the pilot panel, the co-pilot panel, the centre engine monitoring panel, the centre panel with the two attitude indicators and the pilot’s clock.

The panels were mounted in a mechanical structure that corresponds to the cockpit situation.

The instrument components were produced in very good quality using the resin printing process and then finished, painted, glazed and assembled.

This replica of the cockpit instrumentation is unique in the world and demonstrates the outstanding quality of our research and design.

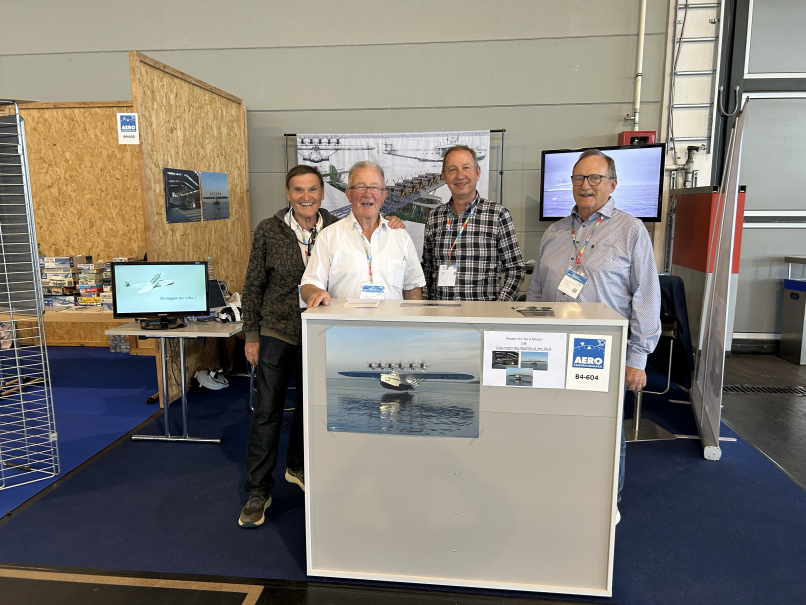

The cockpit instrumentation of the Do X can be viewed at the Aero Aviation Fair in Friedrichshafen from 17 to 20 April. The association of friends and sponsors Do X will once again be taking part in this year’s Aero and can be found in hall B4 at booth B4-604.

Start of the cockpit reconstruction (November 2023)

In the replica of the Do X we are currently in construction stage A, the foreship. This stage also includes the interior fittings of the cockpit and navigation compartment.

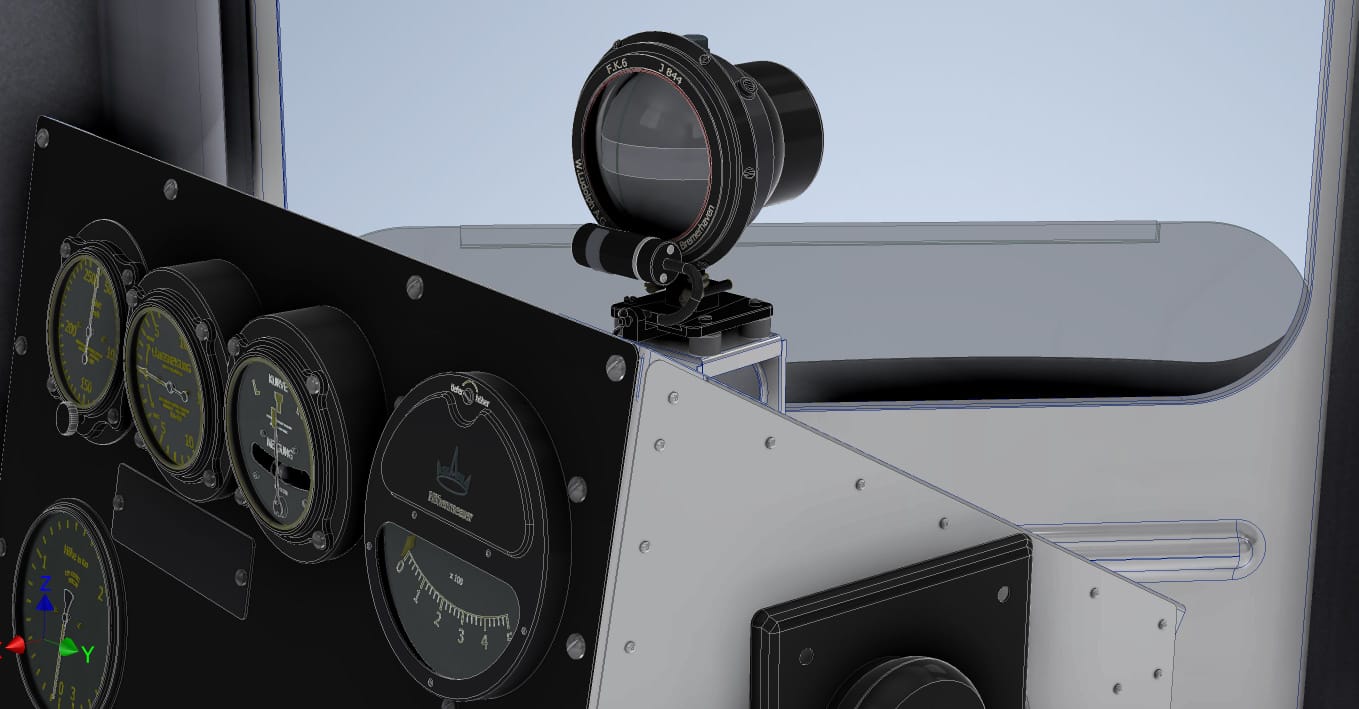

We are actually at the very beginning of the construction of the foreship, but it turned out that we got in touch with Mr Waldmann from the company Waldmann 3D, a specialist in prototype construction with years of experience in replicas of aircraft instruments, who can build the cockpit instrumentation true to the original based on our data.

However, this reproduction of the cockpit instrumentation is only possible thanks to the fact that our member Steffen Harbusch carried out the preliminary design work in exorbitant detail.

Based on this design data, Mr Waldmann will rebuild the cockpit instrumentation piece by piece.

The high-precision replica of the first instruments from the pilot’s side, the Ludolph F.K.6. pilot’s compass, an Askania altimeter and a Pionier longitudinal inclination instrument are already finished. The centre control panel for the engines with operating lights for the engines and the total speed indicators are also ready.

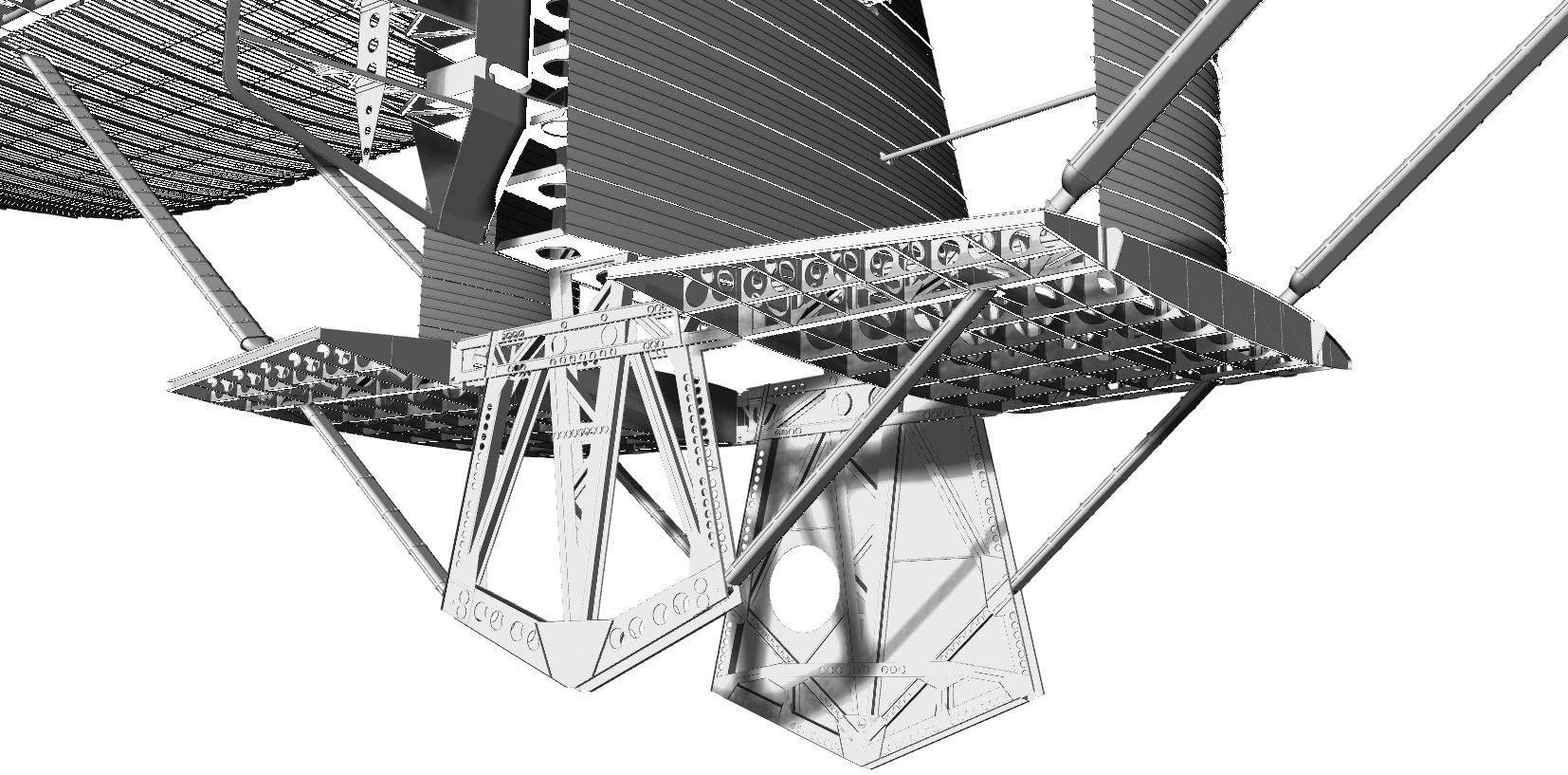

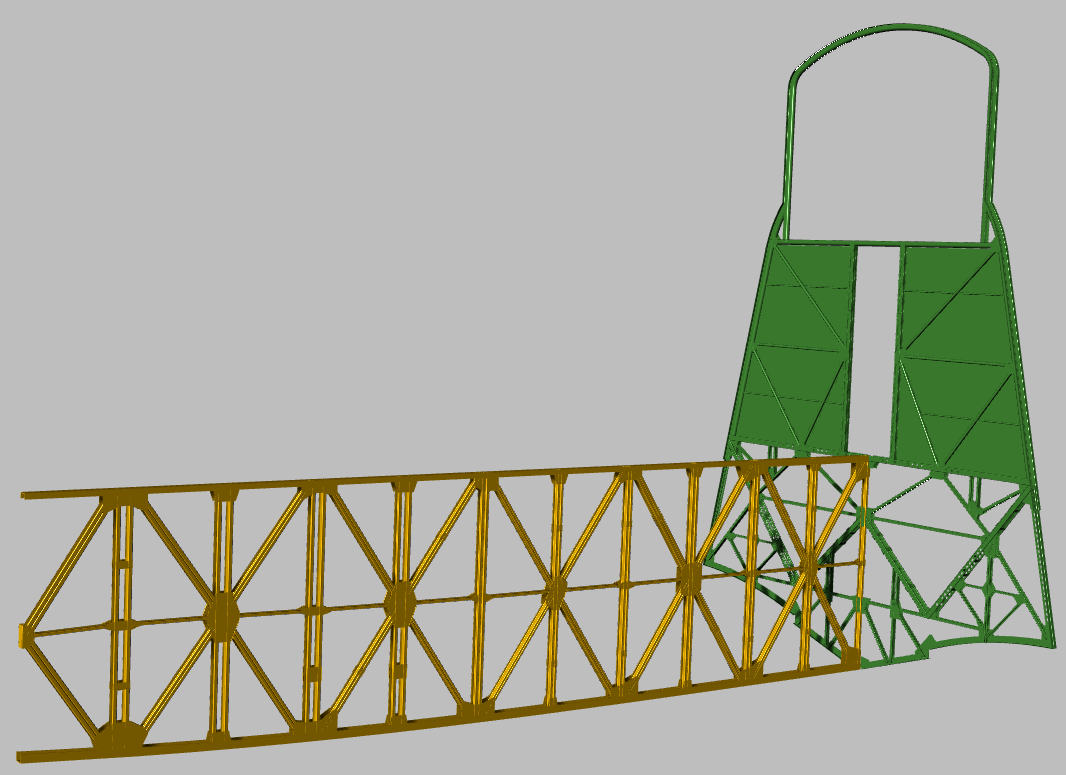

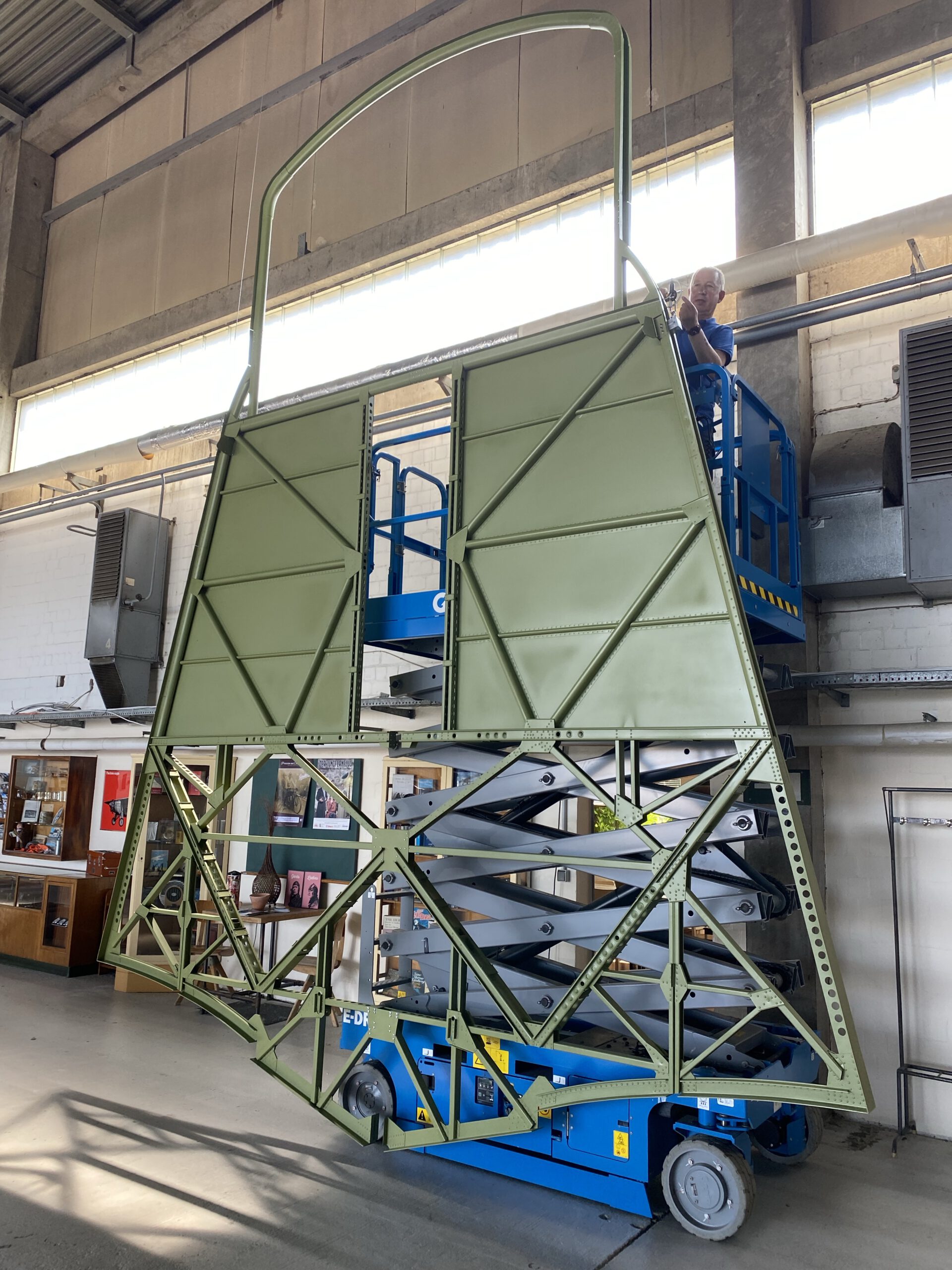

Do X construction stage A (“foreship”) has reached the third dimension (October 2023)

The replica of the Do X has made further progress. In October, the completed centre longitudinal beam (part of the foreship) was connected to rib 44. Before that, a slipway and the support for rib 44 were built. This substructure is already prepared for the supports of the next ribs. The construction took about 1.5 days. The following video shows parts of the construction from the setting of the substructure (slipway) to the installation of the cabin floor between frame 44 and frame 47 in fast motion.

Freundeskreis Do X CAD model for the Microsoft Flight Simulator

Our Do X is now also flying in the Microsoft Flight Simulator. The model is based on our data and was modified by Microsoft for the flight simulator. Here the announcement of Microsoft for the Do X model and a video of the Freundes- und Förderkreis Do X e.V. as a partner of Microsoft.

Do X landing outside Friedrichshafen

Here is a nice video of a Do X landing in front of Friedrichshafen. The video was created on the basis of our CAD data using the Blender tool (sound ON!).

August 2023: The build of the centre longitudinal beam for the foreship is finished!

The build of the centre longitudinal beam for the foreship is finished and will soon be delivered to Hildesheim. The integration with frame 44 will not take place until October 2023. Before that, the slipway and a support for frame 44 still have to be manufactured. These components will not be delivered until October.

New results regarding the reconstruction of the Do X

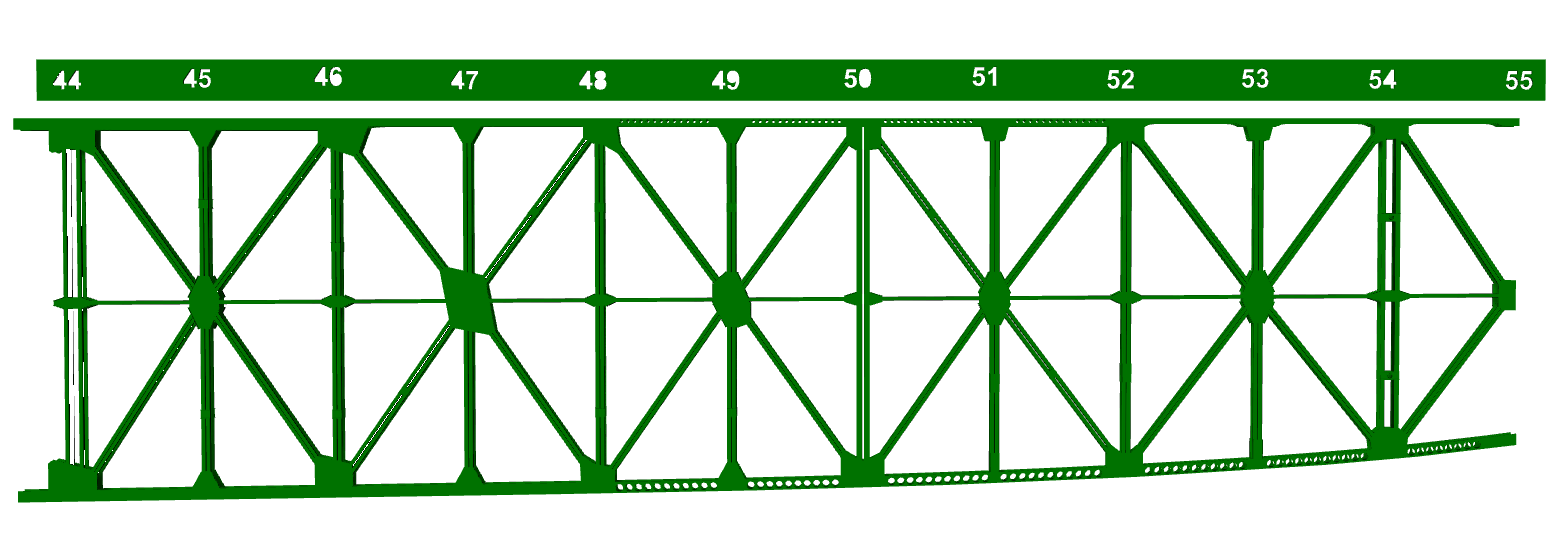

And there are also new developments regarding the reconstruction of the Do X. In mid-June, the Friends of the Do X celebrated an important milestone in its reconstruction. On this day, the students of the 9th year handed in the final data of the detailed construction of the tail unit. With this complex component, the reconstruction of the Do X has made good progress. The G9 construction included the fin with rudder and auxiliary rudder, the tailplane with rudder, auxiliary tailplane and balance surfaces, ribs 3 and 6 (the tailplane is attached in these ribs), the stabs and the control system for the tailplane and fin.

The next step is the detailed construction of the wing.

Details of the tail unit construction are shown in the following pictures.

The next component will be built!

Now that there is a perspective for the replica, the next component, the centre longitudinal beam (MLT) of the foreship, has already been commissioned. With this 8-metre long and 2-metre high component, the replica of the Do X enters the third dimension. The centre longitudinal frame is the load-bearing component for the integration of all frames and will be connected to frame 44 in November. The following pictures show the state of construction in November 2023 and current shots from the construction phase of the centre longitudinal beam at the company Ali Storiche 57.

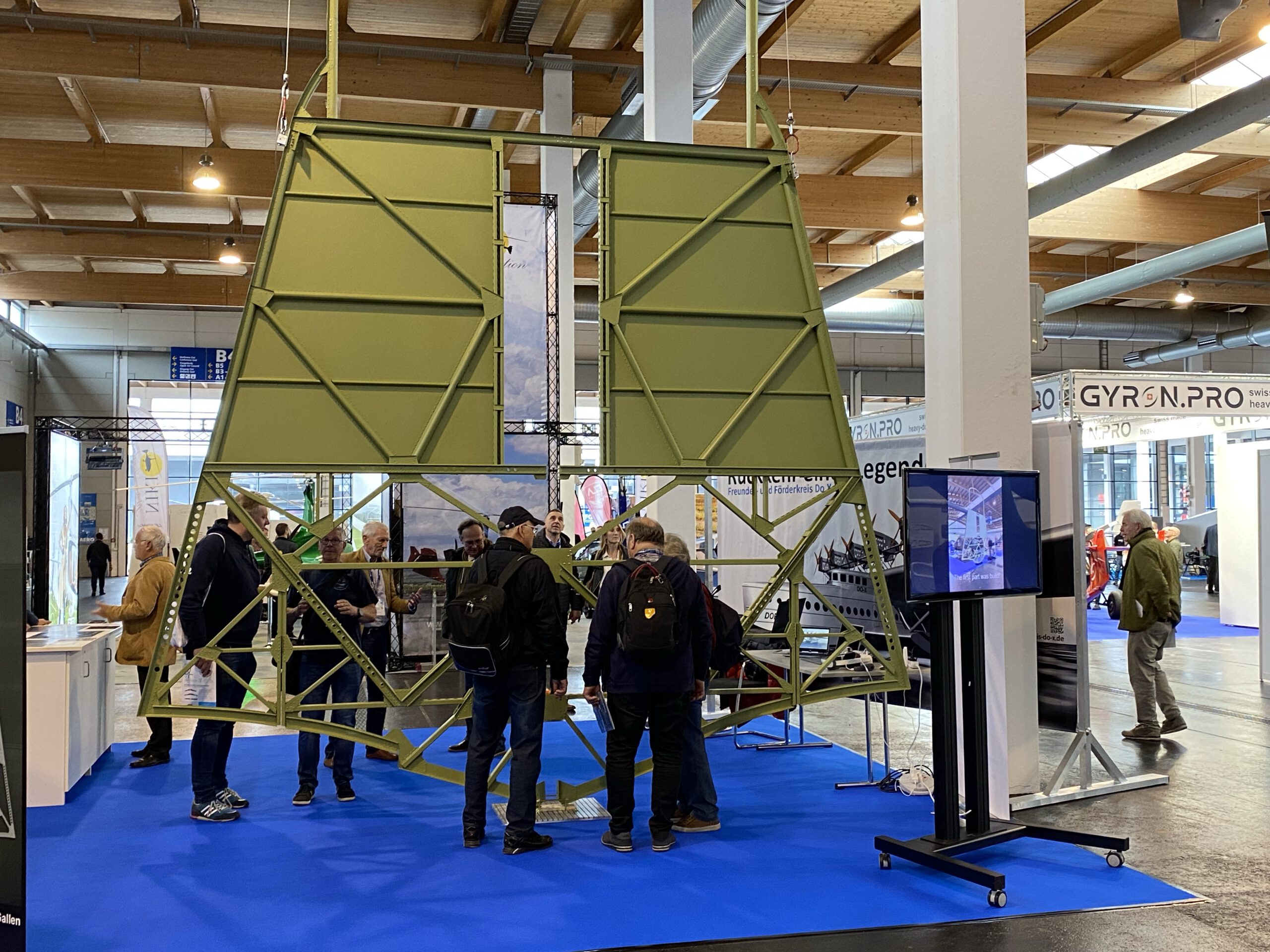

Participation at Aero Exhibition 2023

At this year’s Aero 2023 in Friedrichshafen, an important course was set for the future of the Do X rebuild. A contract was signed with the owner of the Aviators Farm, Thomas Schüttoff, in Hildesheim for the construction and placement of the Do X in the hangar there. This means that there is finally a place and a perspective for the construction of the Do X. Until now, the first frame 44 had been stored in the garage of a member of the association and further building was not possible.

From June 2023, the rebuild will now take place in Hildesheim in the hangar of the Aviators Farm. The first component, frame 44, is already suspended there. The next component to be integrated will be the centre longitudinal frame in November. The circle of friends presented itself with frame 44 and a video/virtual reality show at the Aero 2023.

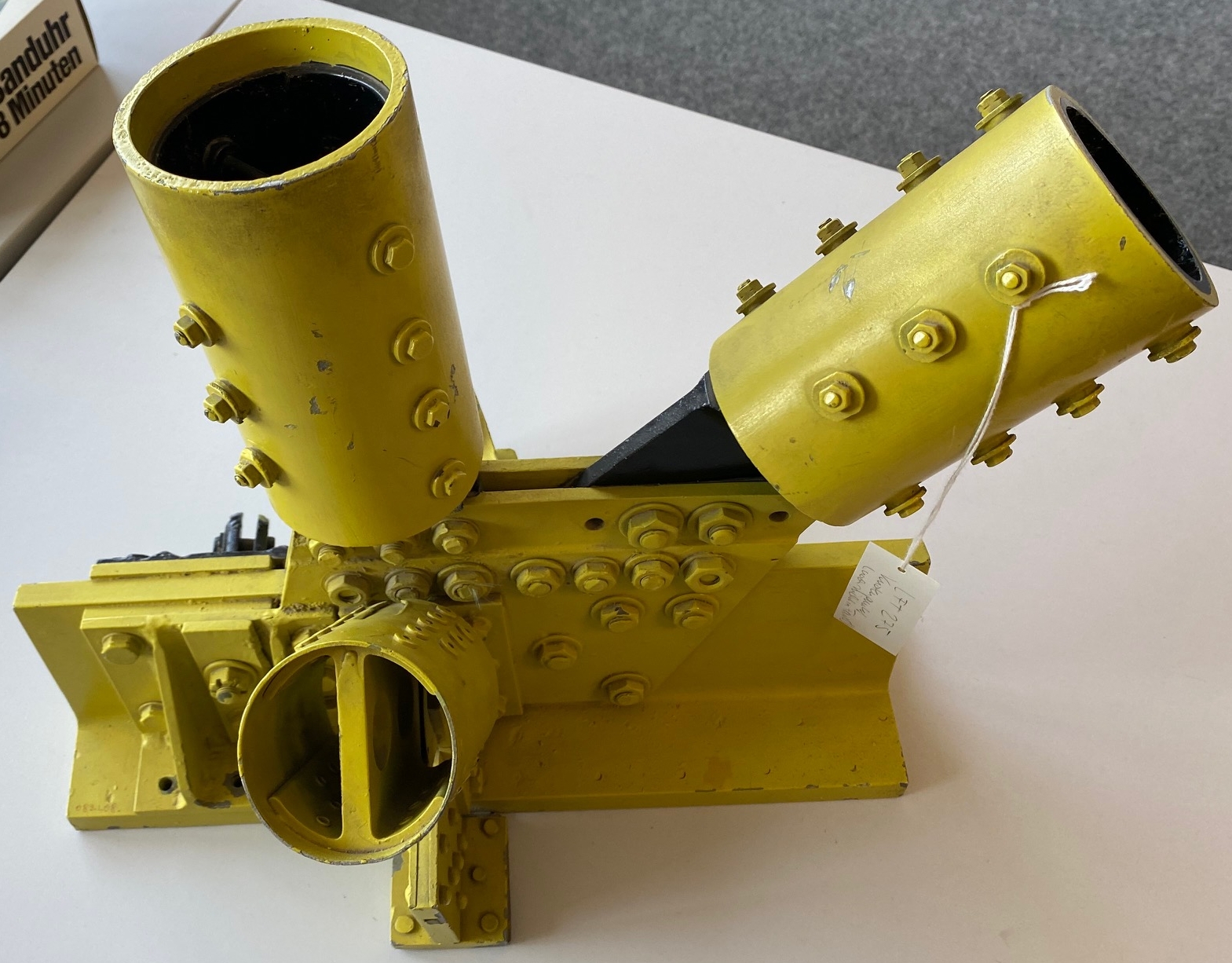

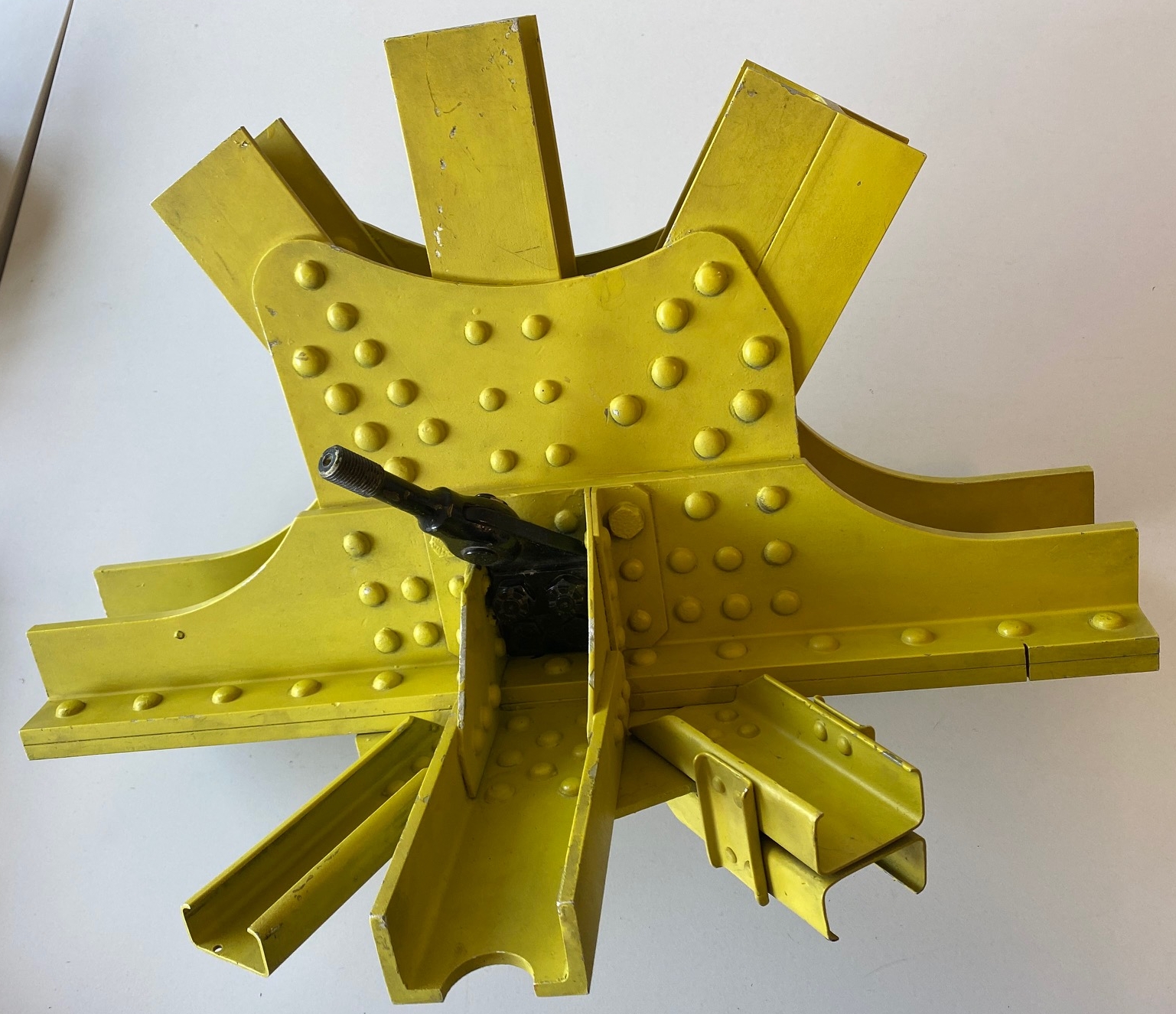

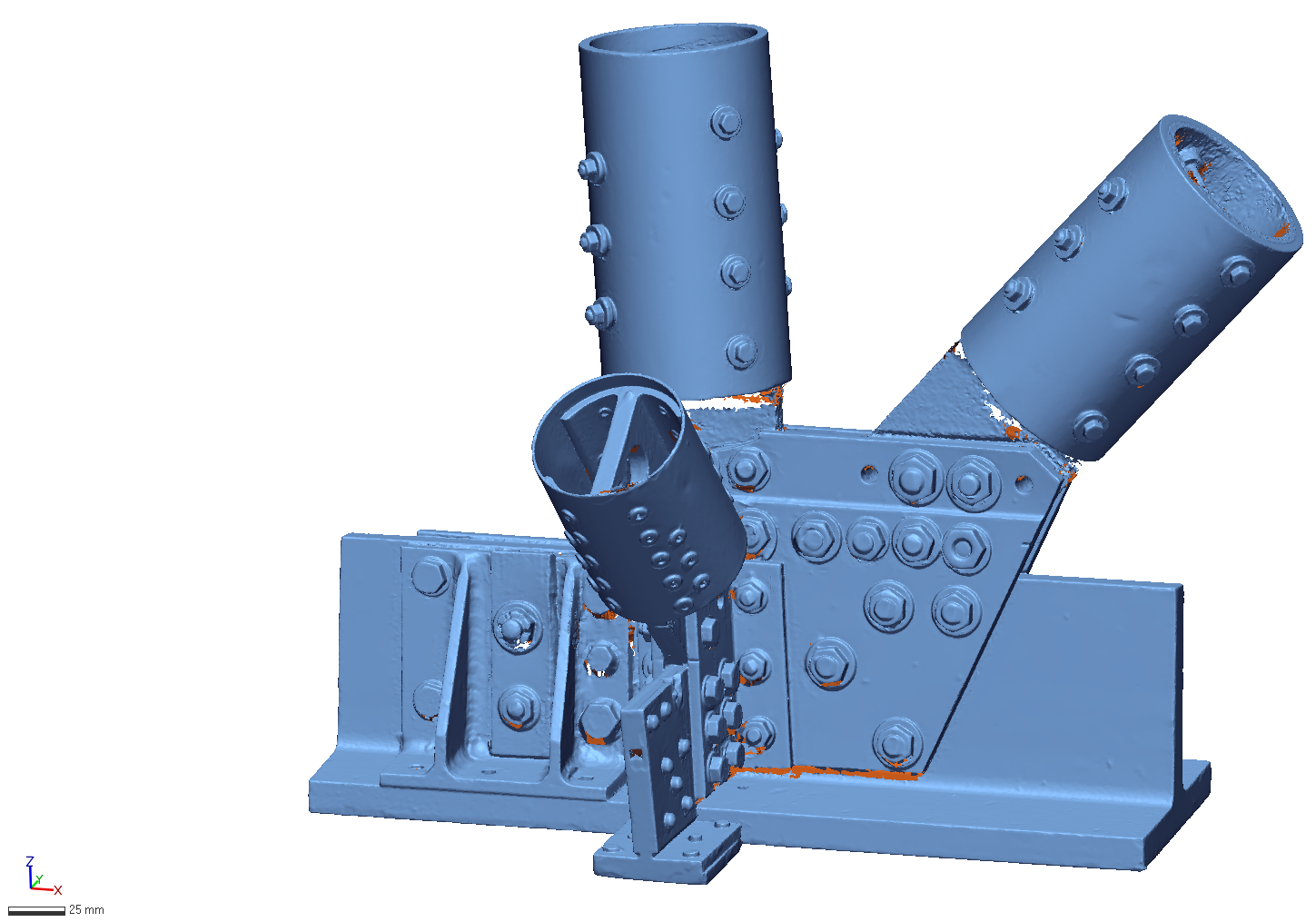

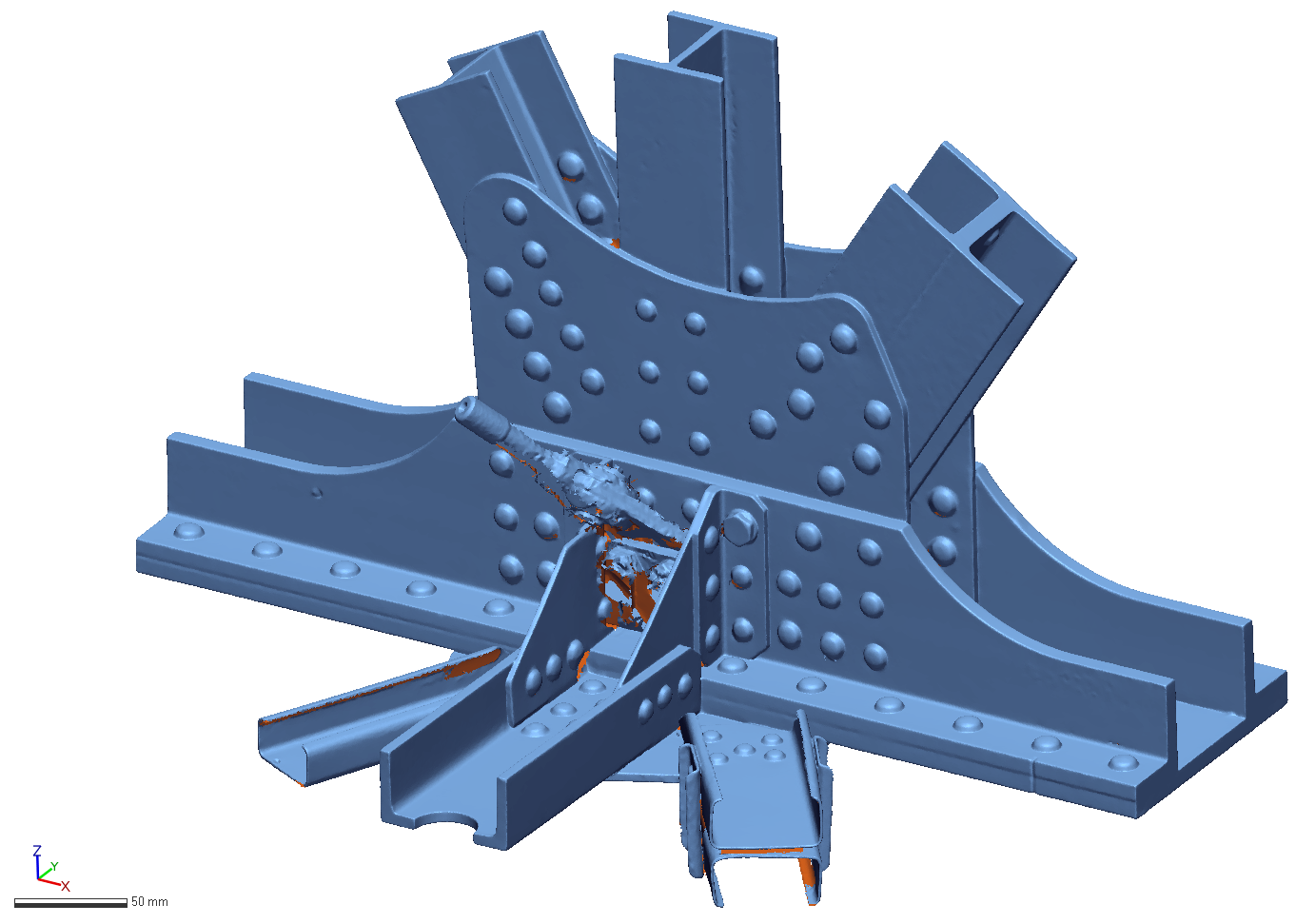

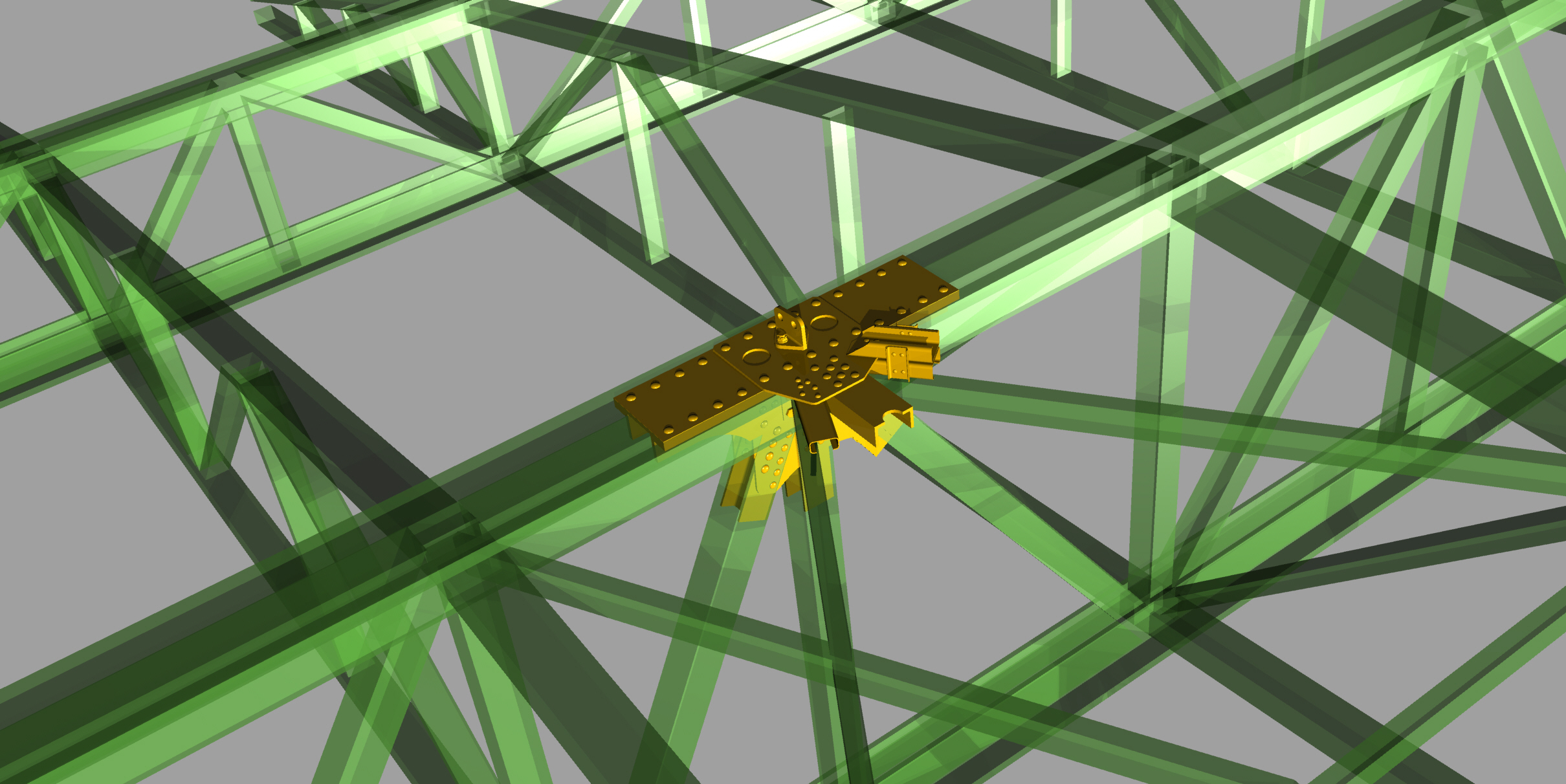

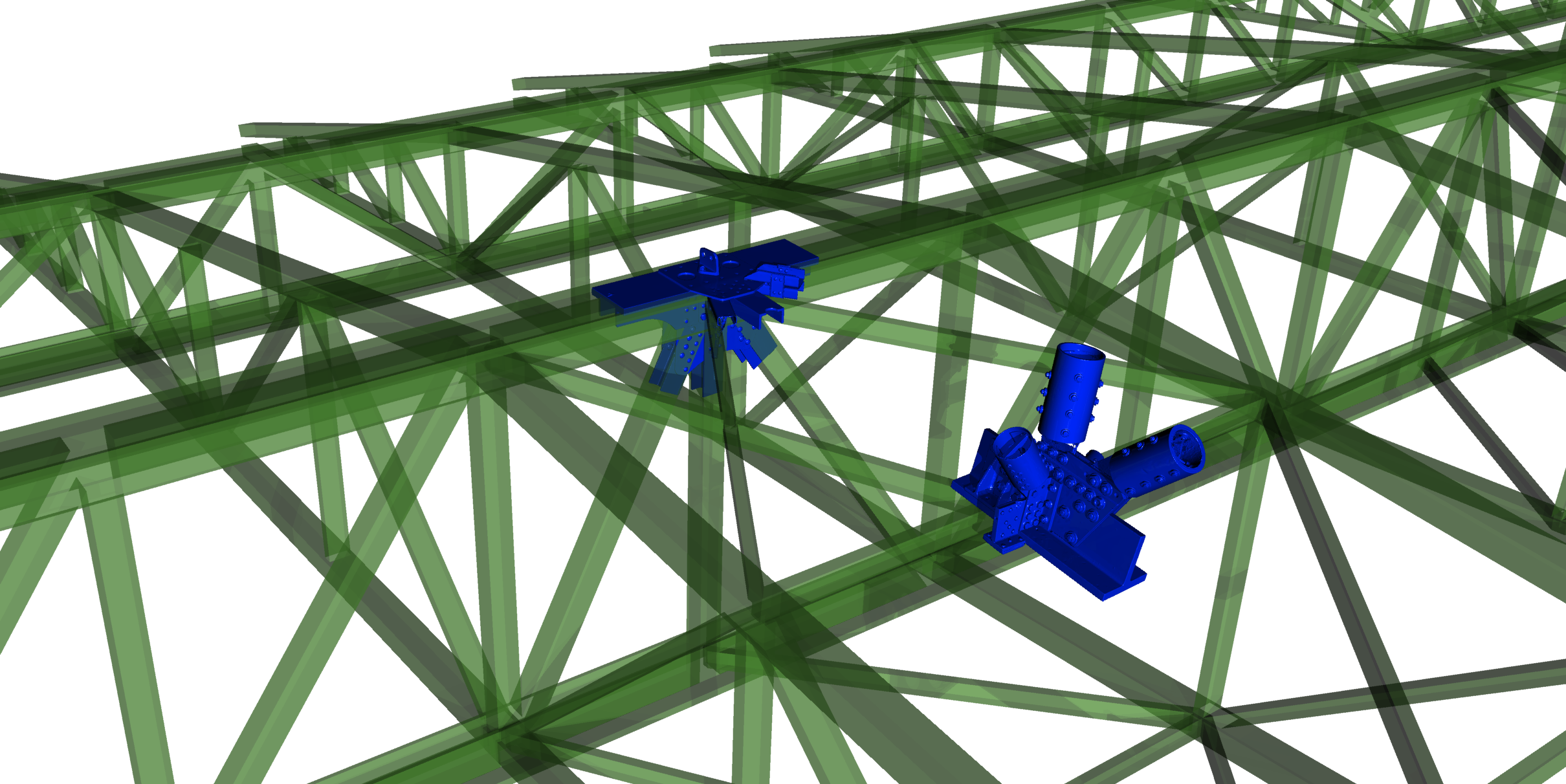

3D capture of Do X structural nodes of the Do X wing (May/June 2022)

While researching documents and artefacts of the Do X in Italy, we came across a collection of a professor Gabrielli at the Turin Polytechnic. In this collection are structural parts of the Do X’s wing structure. It is not clear if these parts were cut out of the scrapped Italian Do X machines or if they were specially built. But the fact that the parts are dented and bent suggests that they came from the Italian Do X aircraft.

Three of the five structural parts of the Gabrielli Collection (©Politecnico di Torino)

There is a total of five Do X structural parts in this collection. Three of which obviously originate from the Do X wing structure. Two parts are obviously rebuilding of the original parts. Two of the five parts (middle and right picture) are currently on loan from the Turin Polytechnic in the archives of the Dornier Museum in Friedrichshafen.

Since the next stage in the reconstruction of the Do X is to reconstruct the wing structure and the information available here is not as extensive as for the fuselage, it would be helpful to measure these structural parts or, even better, to record them three-dimensionally.

Mr. Nietfeld, owner of the company ncd Nietfeld GmbH, kindly agreed to capture the two structural parts in the Dornier Museum for the Friends of the Do X using laser technology. What was still missing was the approval of the person responsible for the collection at the Turin Polytechnic. The circle of friends received this too. So there was nothing against the 3D scanning.

The 3D capture was carried out by the company ncd Nietfeld GmbH on 18.05.2022 in the archives of the Dornier Museum and took about two hours. The results of the capture can be seen in the following two pictures.

The captured pixel data was converted by the company Nietfeld into an STL format, in which surfaces of the structural part are approximated via triangles, and made available to the Circle of Friends at the beginning of June.

The Friends and Sponsors of Do X would like to thank the company ncd Nietfeld GmbH for the 3D capture of the Do X structural parts.

A first analysis of the received data showed a very good usability for the Do X project. Michael Schlieb immediately started to convert the data into a CAD model.

During this conversion, the structural parts were found to be warped and bent. This circumstance supports the thesis that these parts were not specially manufactured, but were obviously cut out of the supporting structure of an Italian Do X. The fact that the cut edges run through the middle of the rivets also supports this theory, because no models were built in this way.

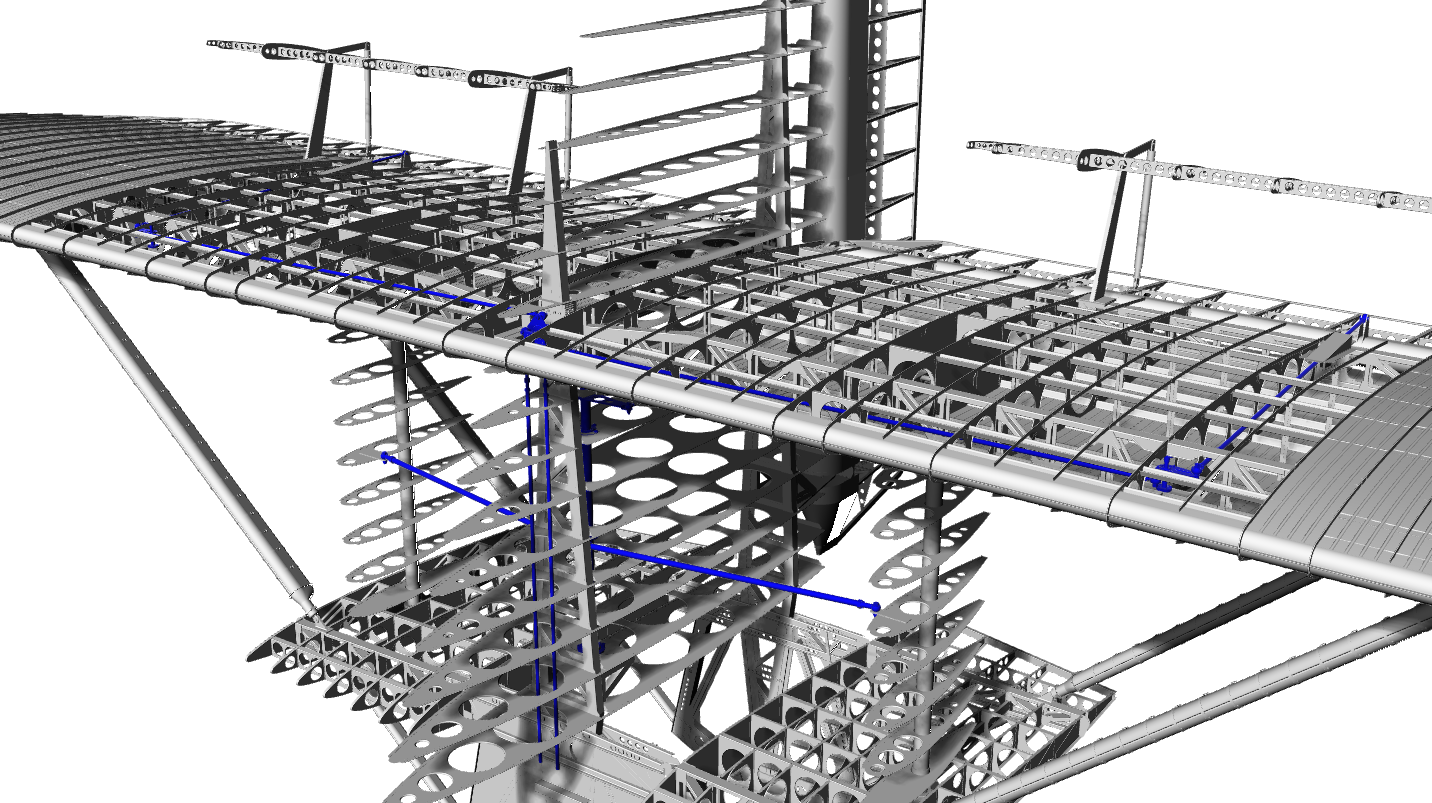

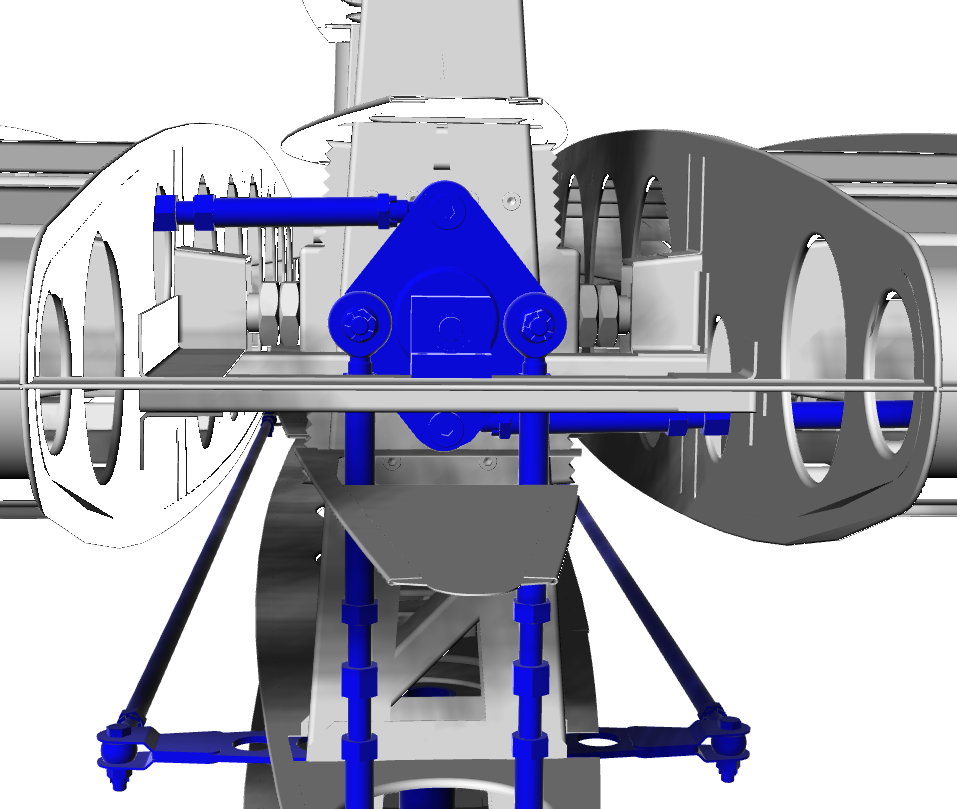

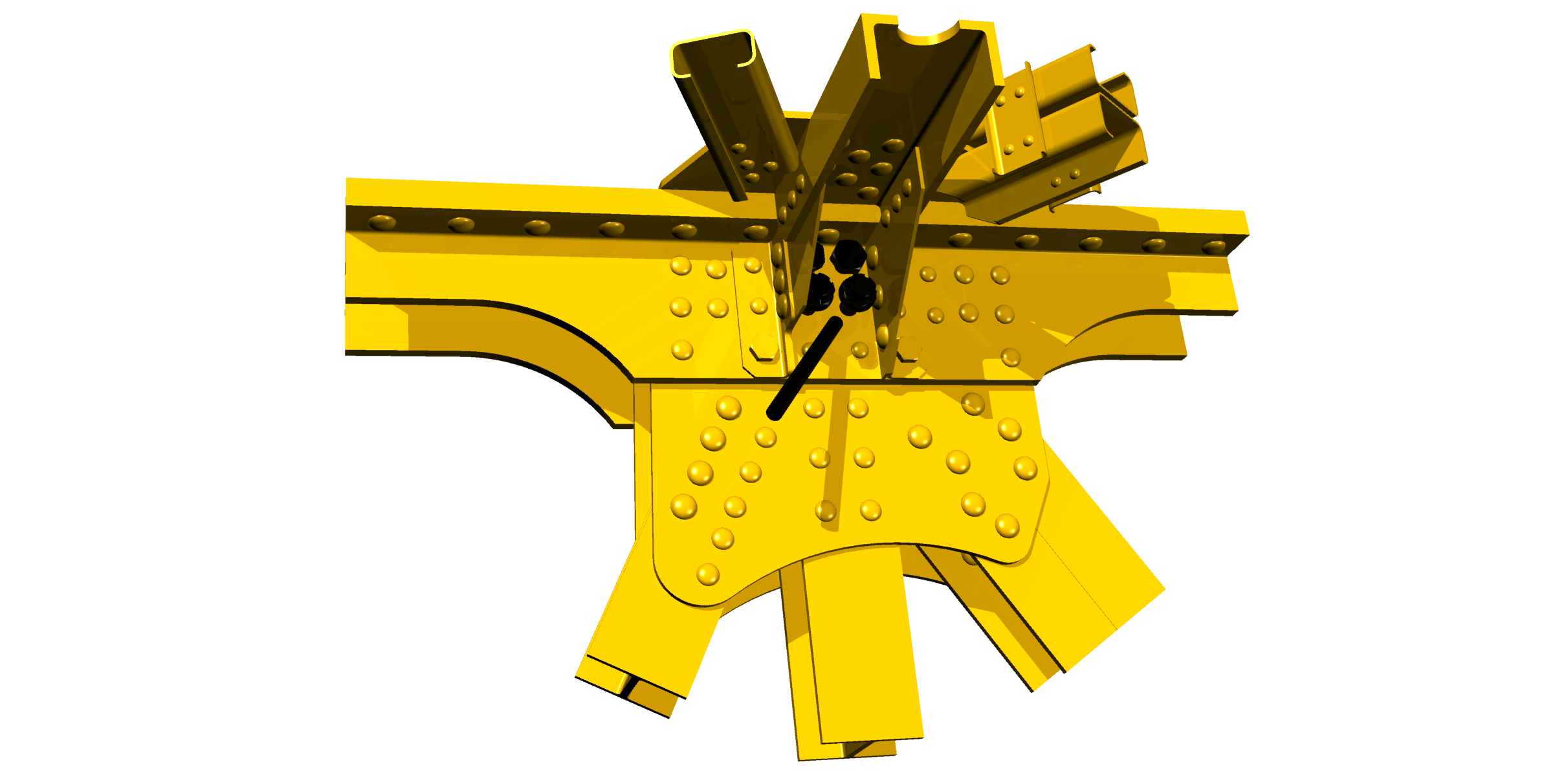

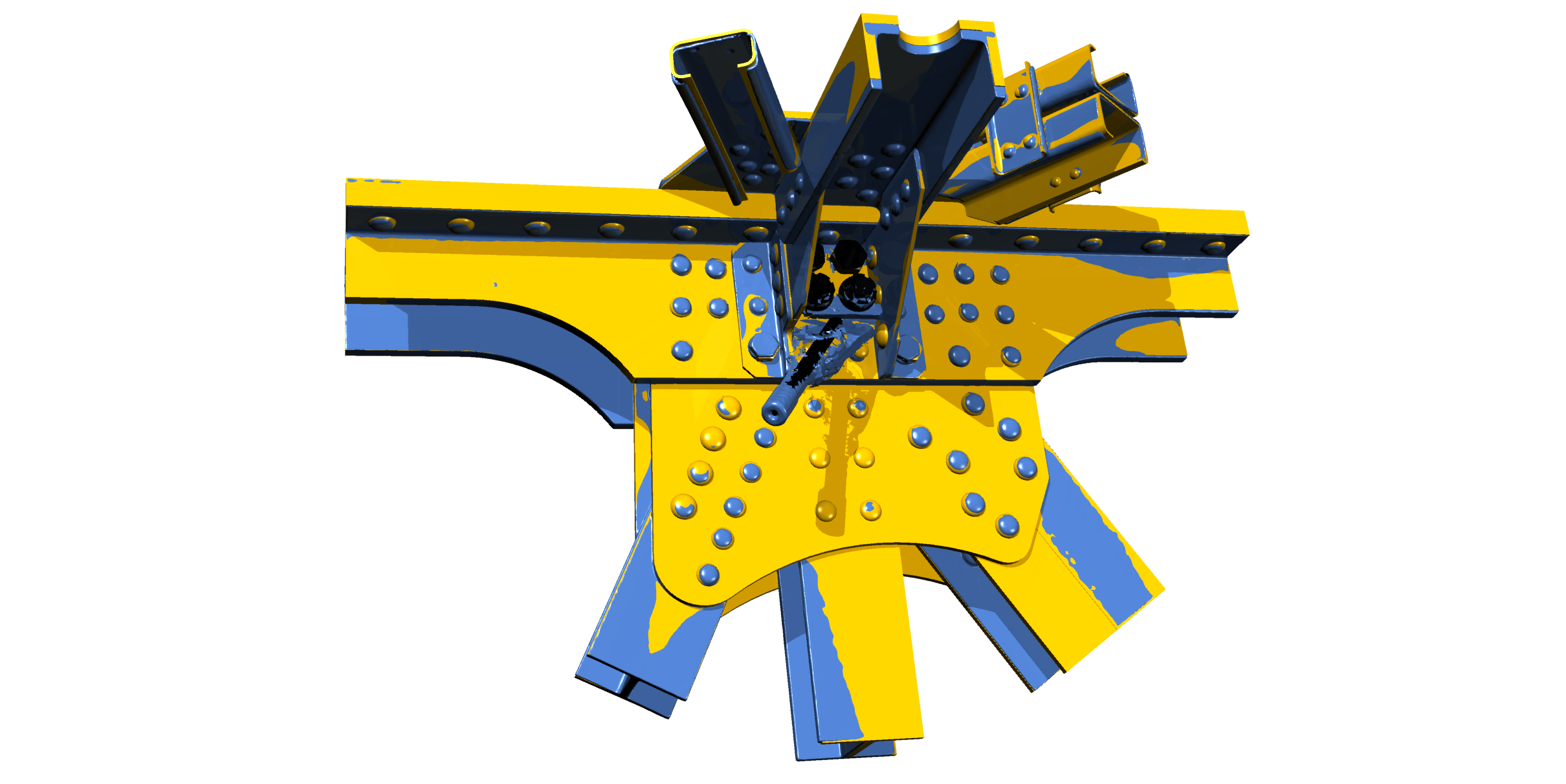

The following picture shows the CAD conversion with the scan data (blue). The illustration shows the deviations of the structural parts from the ideal CAD construction.

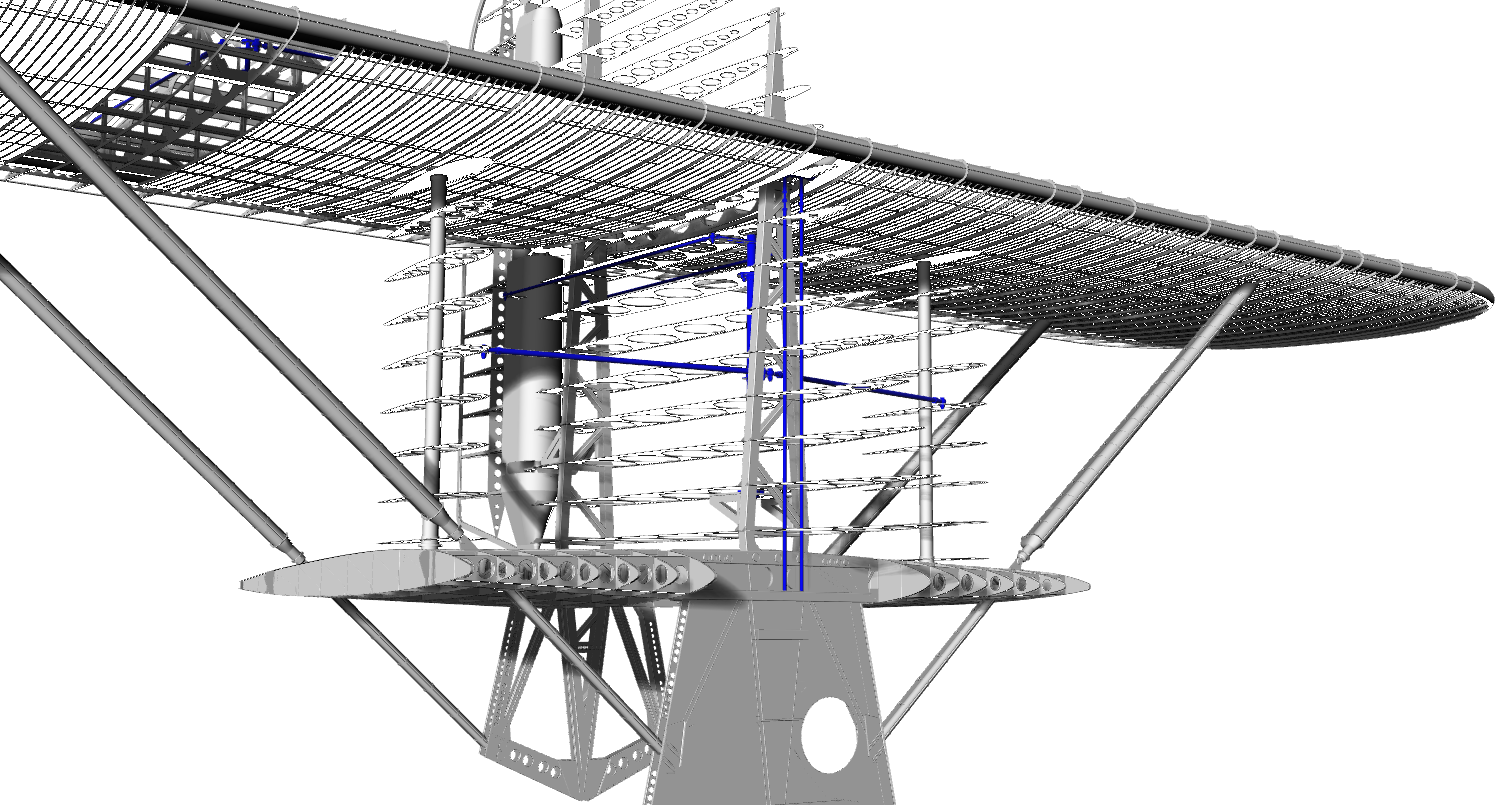

After the CAD conversion was available, the position and orientation of the structural parts in the construction of the Do X had to be found. Since the structural parts obviously originate from the wing structure of the Do X, the available pictures of the wing structure were examined more closely. A match between the structural parts was found in the area of the middle two engine at the centre spar.

A structural part could be inserted directly into the corresponding position of the overall structure and fitted very well. The following two pictures show the corresponding location within the Do X.

The structural parts give important information about the dimensions of the materials used. In this case, the structural part shows that the dimensions of the spar in the pre-construction were assumed to be too large and it shows that a cross-connection in the pre-construction is missing.

Node 1 could be identified as the installation point for the supports of the engine nacelles on the wing structure. Unfortunately, the Italian nacelles differ somewhat from the German version because other engines were used. Nevertheless, this component provides information on the dimensioning and the constructive approach of the time.

We are grateful for every piece of the puzzle that enables us to rebuild the Do X even more accurately.

At this point we would like to thank again the company ncd Nietfeld GmbH and Mr. Nietfeld for the 3D capture of the structural parts and the support of the Do X project. We would also like to thank Mrs. Bongiovanni and Mr. Mattone from the Turin Polytechnic for granting us the 3D capture of the structural parts.

Do X Presentation at the Aero 2022 Trade Fair Friedrichshafen (Aril/May 2022)

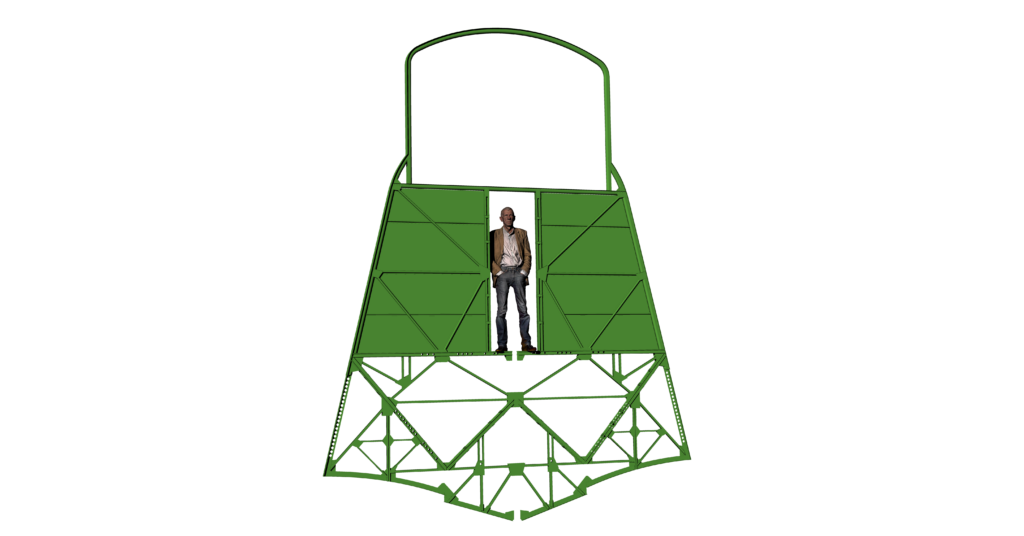

The Aero 2022 trade fair was the first opportunity to present the Friends and Sponsors of Do X to the public. Until this occasion, the association had always been held back by the Corona situation. At the Aero 2022 exhibition we were also able to present the foundation stone for the Do X, frame 44, to the public for the first time. The association received part of the exhibition space from the Dornier Museum.

The Do X booth featured the rib 44, a system to display a Do X Virtual Reality Show, a monitor to display a video showing the creation process of the rib from design to production, a large format poster of the Do X as another eye-catcher and a roll-up with the original photo of rib 44 for comparison with the manufactured rib.

The biggest challenge for the exhibition was the presentation of the rib, because this 6 m high, 4.8 m wide and approximately 90 kg heavy exhibit had to stand upright in the hall. So the project management of the trade fair was approached to find out whether it would be possible to suspend the frame from the ceiling of the trade fair hall. After the most important data (dimensions/weight/suspension points) of the exhibit were sent to the project management, we received permission to mount the rib on the ceiling.

Approximately two weeks before the start of the trade fair, the planning of the trade fair stand was carried out in cooperation with the Dornier Museum. On the basis of a hall and ceiling plan and a CAD draft of the planned exhibition stand, it was determined with the museum how the exhibits and other objects were to be set up.

Two days before the start of the fair, a special company attached the suspension for the frame to the ceiling construction. The height of the suspension was adjusted so that the frame hovered about 5 cm above the floor. The final distance could still be adjusted. On the same day, the frame was delivered from Hungary. The exhibit had been delivered in three partial segments and had to be assembled first. For the division of the rib, the arch of the cockpit roof was removable and the remaining part of the rib was divided in the middle, where the connections to the centre longitudinal frame would later be located.

The assembly of the rib was carried out by members of the Do X Circle of Friends according to assembly instructions from the manufacturer and took about an hour.

The rib is provided with two suspension eyes at the level of the cockpit floor to enable the rib to be suspended. To raise the bulkhead, ropes were passed through the eyelets of the suspension to the suspension eyelets of the bulkhead and fastened there. By pulling on the other end of the rope, the rib was slowly raised. After the rib was upright, the eyes of the rib and the suspension were connected by shackles. The frame was also fixed to the ground with a solid metal plate so that it could not swing.

One day before the opening of the fair, the remaining booth components (TV monitor, virtual reality system, poster and roll-up) were set up. The virtual reality system consisted of two VR glasses and a VR server.

The VR system presented several Do X scenarios to the viewer. On one pair of VR glasses, the Do X was permanently shown from the outside, in 1:1 of course. In this scenario, the viewer can walk around the Do X and also climb it up to the engines.

On the second pair of VR glasses, the interior of the Do X was shown, such as the cockpit, engine control room, auxiliary engine room, the passenger cabin or the structural framework of the aircraft.

At the end of the preparations, the functions of the VR system were tested again.

During the days of the fair from 27 to 30 April, many people visited the booth and were impressed by the size of the rib as well as thrilled by the VR show. None of the visitors had seen the Do X like this before.

Here are some scenes from the VR show:

Here is the comment of Nelson Vaz (Head of Marketing and Sales of Dornier Seawings) : „The VR experience is remarkable. The level of detail and sense of reality is truly outstanding. By walking around the Do X one could have an enhanced perception of the extraordinary physical dimensions and unique design characteristics of this dream machine. For a few minutes I was transported to another place and time, really enjoyed it.”

All in all, the participation at the Aero 2022 was a great success for the Freundeskreis Do X. Thanks to the Dornier Museum, which made this participation possible.

On 1 May, the stand was dismantled again. The frame was dismantled into three segments to make it easier to transport and store. Unfortunately, there is no better place for the frame than in the garage of a member of the Do X association.

————————— The foundation stone for Do X is ready —————————

The first component for the replica of the Dornier Do X airship is ready. It took a good 8 years to produce the first component from nothing, as there were no more detailed design plans. The reconstruction of the Do X began in 2014. Since then, a total of 112 students from the Cooperative State Universities in Friedrichshafen, Mosbach and Lörrach have worked on the Do X project, putting in 33600 hours.

In the three phases, strak creation, pre-construction and detailed construction, construction plans were created again from a few general drawings and pictures from the construction phase of the airship. These blueprints are as accurate as possible to allow an original replica of the Do X.

The now completed rib 44 underlines this originality and the claim of the Freundes- und Förderkreis Do X e.V. to rebuild the legendary flying ship Do X as true to the original as possible. The component corresponds 99% to the original rib of the Do X. Deviations are only caused by inaccuracies in the measurement of the used general arrangement drawing or pictures. And the rib proves impressively that a reconstruction of the Do X is no longer impossible.

The rib 44 was built by Ali Storiche 57, a company that already built the Dornier Wal and the Dornier Merkur aircraft.

The used general drawings and pictures from the

construction phase of the Do X would be kindly provided to the association by

the State Archives St. Gallen.

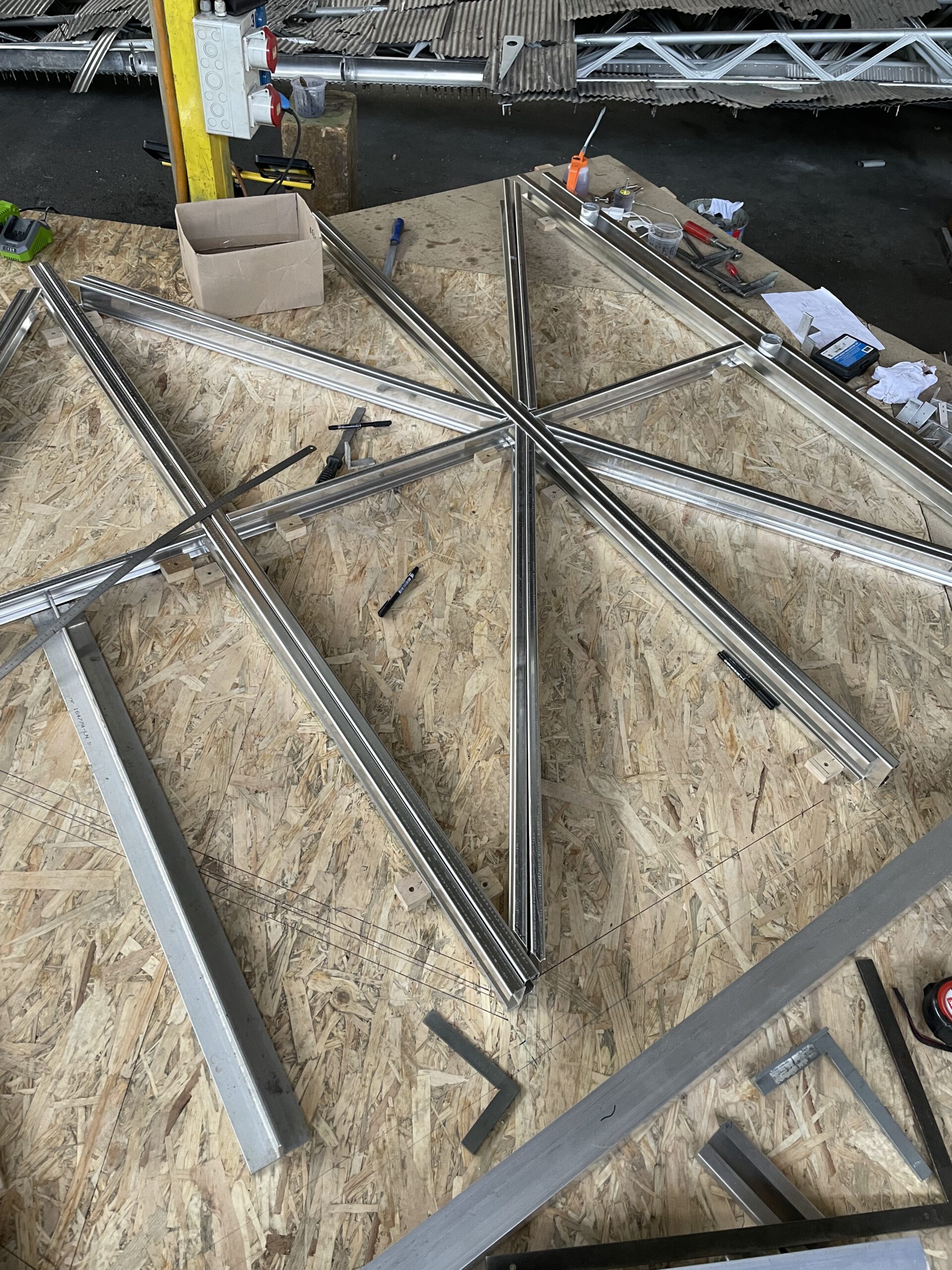

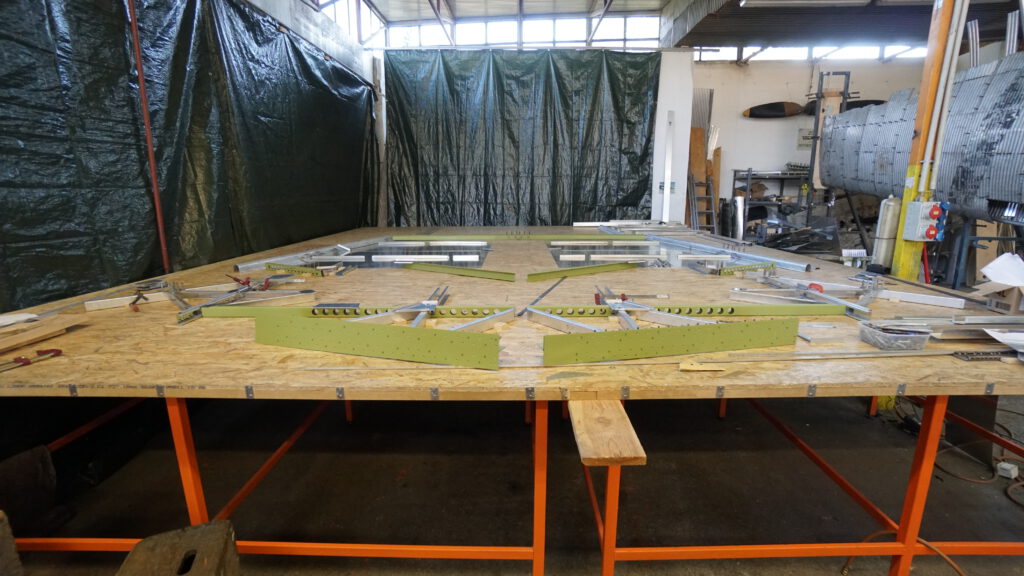

————————— The building phase of rib 44 from September to November 2021 —————————

The first component for the replica of the Do X will be the fuselage frame 44. This gigantic component, measuring 6 x 4.60 m, is the cornerstone for the replica of the legendary Do X.

In addition to the pure presentation of the component, the rib is intended to prove that a replica of the Do X is possible in principle and true to the original. The first rib produced underlines this originality and the claim of the Freundes- und Förderkreis Do X e.V. to rebuild the legendary flying ship Do X as true to the original as possible.

Rib 44 was ordered in August 2021 and will be built in Hereg, Hungary, by Ali Storiche 57 kft. This company has also already produced the Wal aircraft and the Merkur aircraft for the Dornier Museum in Friedrichshafen.

Before building Do X ribs, a new integration table had to be built for assembling the components due to the dimensions of the ribs. The table has the dimensions of the largest Do X rib (6.5 x 5 m) and is constructed from two partial tables.

The subcomponents (profiles) are largely manufactured by hand. As these are individual items and not series production, machine production of special profiles, for example by rolling, would be uneconomical.

Various types of profile, such as U-profiles, U-profiles with board, L-profiles, T-profiles, square profiles and A-profiles, are required for the production of frames. In the case of A-profiles, a distinction is made between normal A-profiles and A-profiles with adjustment to the shape of the fuselage.

The production of A-sections proceeds as follows. First, an approximately 150 cm long steel master mold is made for the outer rounding of the A-section. This master mold is placed in a press. A cut-to-size strip of aluminum is first placed on this master mold, followed by a steel tube for the inner rounding of the A-section. Then the press is used to press the steel tube into the master mold by means of a wooden board, thereby shaping the aluminum. Next, the shaped aluminum is clamped in vices and the two tabs are chamfered by hammer blows. To finish, the A-profile is straightened if necessary. If longer profiles such as the parts produced in this way are required, then several elements of the A-profile are riveted together.

U-profiles and U-profiles with board are produced on the bending bench. For a U-profile, the prepared aluminum strip is bent twice on the long sides in the bending machine. For a U-profile with a board, the folded sheet is folded again on the long sides.

L-profiles are also produced in the bending bench. T-profiles are made from two L-profiles. Square profiles are parts that are purchased.

And here are some pictures from the Rib 44 production

————————— Successful completion of the 7th year of the Do X reconstruction in July 2021. —————————

Currently, 41 students from the Cooperative State Universities in Mosbach, Lörrach and Friedrichshafen are working on the detailed reconstruction of the Do X. Within the scope of this effort, the construction of the Do X fuselage will be nearly completed by July 2021.

At the end of this effort, a total of 112 students will have worked on the project, putting in 33600 hours.

The result of the work at the Jour Fix in February 2021 is shown in the following pictures. The Do X is composed of detailed construction (green elements), pre-construction (gray elements) and strak (outer skin).

en

en de

de